When it comes to sandblasting, it is crucial to prioritize clean and safe air.

But with so many air purifiers available, how do you know which one is the right fit?

Well, fear not, because I’m here to guide you through the process.

In this article, we’ll explore the different types of air purifiers specifically designed for sandblasting environments.

From HEPA filters to activated carbon filters, we’ll cover it all.

So let’s dive in and discover the ideal air purifier for your sandblasting needs.

Key Takeaways

- Clean and safe air is crucial in sandblasting operations.

- Adequate air purification systems, such as HEPA filters, are necessary to remove harmful particles.

- Safety is a top priority in sandblasting operations, and effective filtration system is essential to remove harmful particles and contaminants.

- Size and portability of the equipment should be considered for flexibility and ease of use.

Importance of Air Purification in Sandblasting

If you’re sandblasting, it’s important to understand the importance of air purification to protect yourself from harmful particles. Proper ventilation is crucial in sandblasting operations to ensure a safe working environment.

When sandblasting, various particles and contaminants are released into the air, including silica dust, metal fumes, and toxic chemicals. These airborne particles can pose serious health risks if inhaled. Without adequate air purification, workers can develop respiratory problems such as silicosis, lung cancer, and respiratory tract infections. Additionally, prolonged exposure to these hazardous substances can lead to long-term health complications.

To mitigate these risks, it is essential to have appropriate air purification systems in place, such as high-efficiency particulate air (HEPA) filters, to remove harmful particles from the air and maintain a clean and safe working environment.

Factors to Consider When Choosing an Air Purifier for Sandblasting

When it comes to sandblasting, ensuring safety is of utmost importance. This involves following specific safety requirements such as wearing appropriate protective gear and working in a well-ventilated area.

Additionally, having an effective filtration system is crucial in order to remove harmful particles and contaminants from the air, protecting both the operator and the surrounding environment.

Lastly, considering the size and portability of the equipment is essential, as it allows for flexibility and ease of use in various work environments.

Sandblasting Safety Requirements

To ensure your safety during sandblasting, make sure you adhere to the necessary safety requirements.

Sandblasting can expose workers to hazardous materials, such as silica dust, which can cause respiratory issues if inhaled. That is why using proper respiratory protection is crucial to safeguard your health.

According to OSHA regulations, employers must provide employees with suitable respiratory protection, such as respirators, to minimize exposure to harmful particles. These respirators should have a NIOSH-approved filter and fit properly to ensure a secure seal.

Additionally, employers must establish a respiratory protection program that includes medical evaluations, fit testing, and training. It is essential to follow these safety requirements to prevent respiratory illnesses and maintain a safe working environment during sandblasting operations.

Effective Filtration System

Ensure that your filtration system is properly maintained to effectively remove hazardous particles and maintain a safe working environment. Here are four important steps to maximize your air purifier’s performance and prolong its lifespan:

-

Regularly clean or replace filters: Over time, filters can become clogged with dust, debris, and other particles. Cleaning or replacing them ensures optimal airflow and filtration efficiency.

-

Check the fan and motor: Inspect the fan and motor for any signs of wear or damage. A malfunctioning fan or motor can reduce the air purifier’s effectiveness.

-

Clean the unit’s exterior: Dust and dirt can accumulate on the exterior of the air purifier, hindering its performance. Regularly wipe down the unit with a soft cloth to maintain its efficiency.

-

Monitor the air quality: Use an air quality monitor to assess the effectiveness of your air purifier. Adjust the settings or consider upgrading if the air quality remains poor despite proper maintenance.

Size and Portability

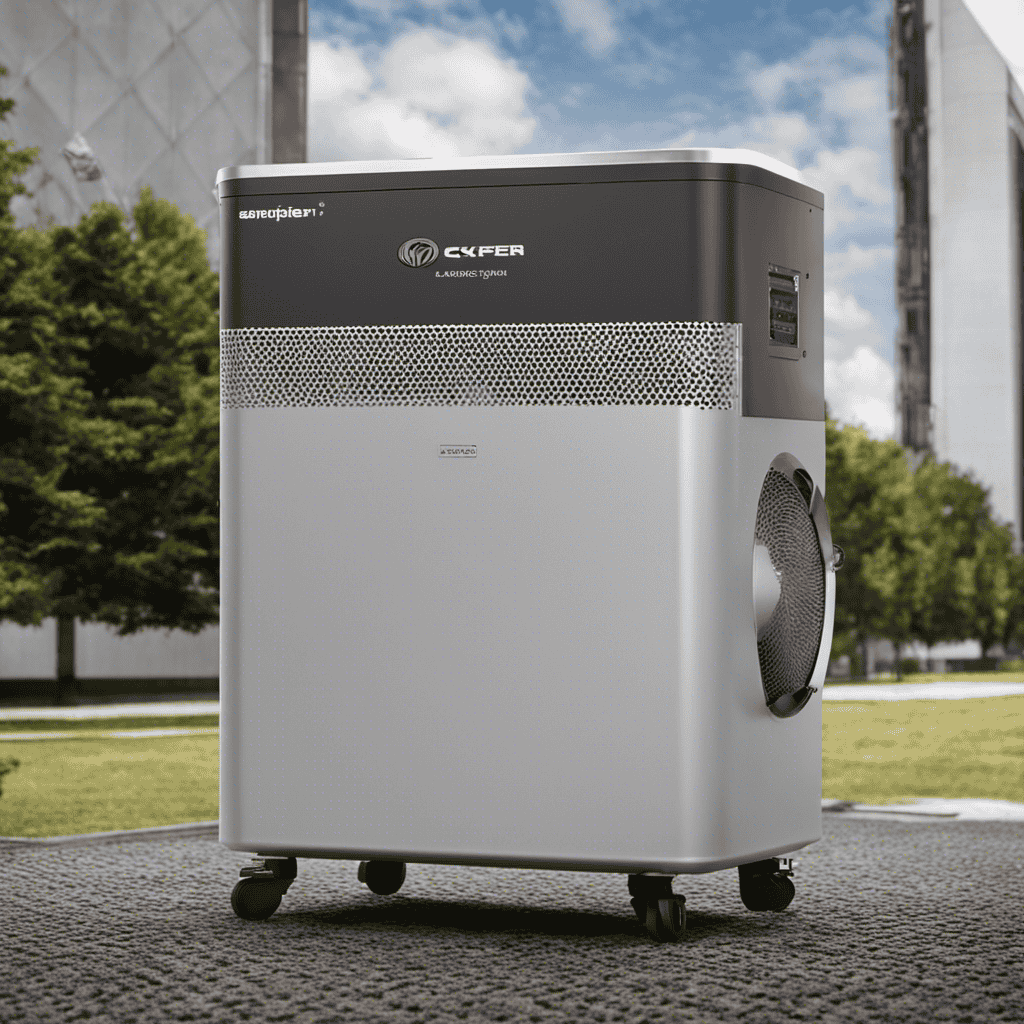

You’ll find that size and portability are important factors to consider when choosing an air purifier for your workspace.

The portability benefits of an air purifier allow you to easily move it around your workspace as needed, ensuring that you can purify the air in different areas.

The size considerations are crucial because you want an air purifier that can effectively clean the air in your workspace without taking up too much space. A compact and lightweight air purifier would be ideal for a small workspace, while a larger one may be necessary for a larger area.

Now that we have discussed the importance of size and portability, let’s delve into the different types of air purifiers for sandblasting.

Different Types of Air Purifiers for Sandblasting

When sandblasting, you can choose from various types of air purifiers to effectively remove contaminants from the air. Here are some different types of air purifiers that are commonly used in sandblasting environments:

-

High-Efficiency Particulate Air (HEPA) Filters: These filters are designed to trap small particles, including hazardous materials like lead and silica dust. They provide excellent filtration and are ideal for sandblasting environments.

-

Activated Carbon Filters: These filters are effective at removing odors and chemical fumes from the air. They work by adsorbing the contaminants onto the carbon surface.

-

Electrostatic Precipitators: These purifiers use an electrostatic charge to attract and capture particles. They are efficient in removing both large and small particles from the air.

-

UV-C Light Purifiers: These purifiers use ultraviolet (UV) light to kill bacteria, viruses, and other microorganisms. They are often used in combination with other air filtration methods.

Using air purifiers in sandblasting environments has several benefits. They help improve air quality, reduce the risk of respiratory problems, and create a safer working environment for sandblasters.

However, among these different types of air purifiers, HEPA filters are considered the ideal choice for sandblasting environments due to their high efficiency in removing hazardous particles from the air.

HEPA Filters: The Ideal Choice for Sandblasting Environments

HEPA filters are highly efficient at removing hazardous particles from the air in sandblasting environments. These filters are specifically designed to capture and trap even the smallest particles, ensuring cleaner and safer air for workers. Their effectiveness lies in their unique construction, which consists of a dense network of fibers that create a labyrinth-like structure. This structure allows the filters to capture particles as small as 0.3 microns with an efficiency of 99.97%. To give you a better understanding of the efficiency of HEPA filters, take a look at the table below:

| Particle Size (microns) | Efficiency (%) |

|---|---|

| 0.3 | 99.97 |

| 1.0 | 99.99 |

| 2.0 | 99.999 |

| 5.0 | 99.9999 |

| 10.0 | 99.99999 |

As you can see, HEPA filters are incredibly effective at capturing particles of various sizes, making them the ideal choice for sandblasting environments where fine particles are abundant. With their high efficiency, HEPA filters can significantly enhance air quality and protect workers from harmful airborne contaminants. In the next section, we will explore another type of air filter that complements HEPA filters in sandblasting processes: activated carbon filters.

Activated Carbon Filters: Enhancing Air Quality in Sandblasting Processes

As an expert in air filtration systems, I’ve found that activated carbon filters offer numerous benefits for enhancing air quality in sandblasting processes.

The unique properties of activated carbon allow it to effectively capture and remove a wide range of contaminants such as volatile organic compounds (VOCs), odors, and hazardous gases.

This not only improves the overall air quality in the sandblasting environment but also ensures the safety and well-being of workers by reducing their exposure to harmful airborne particles.

Benefits of Activated Carbon

One major advantage of using activated carbon in an air purifier is that it effectively removes odors. This is crucial in environments where strong, unpleasant smells are present, such as in industrial settings or areas with high levels of pollution. The activated carbon works by adsorbing the odor-causing molecules, trapping them within its porous structure.

Here are four key benefits of using activated carbon for odor removal and chemical filtration:

-

Versatility: Activated carbon filters can target a wide range of odors, including those caused by smoke, pet dander, cooking, and chemical emissions.

-

Efficiency: The porous structure of activated carbon provides a large surface area for adsorption, allowing it to effectively remove a high volume of odor-causing molecules.

-

Longevity: Activated carbon filters have a longer lifespan compared to other filter types, reducing the frequency of filter replacements.

-

Safety: Activated carbon is a safe and non-toxic material, making it suitable for use in various environments without posing health risks.

Efficiency in Sandblasting

When it comes to efficiency in sandblasting, it is crucial to consider cost-effective solutions that also help with noise reduction. Sandblasting can generate a significant amount of noise, which can be disruptive and potentially harmful to workers.

To address this issue, there are air purifiers specifically designed for sandblasting environments that offer effective noise reduction. These air purifiers utilize advanced noise reduction technologies such as sound-absorbing materials and noise-dampening filters. By reducing noise levels, these air purifiers create a safer and more comfortable working environment for sandblasting operators.

In addition to noise reduction, these air purifiers also provide cost-effective solutions for sandblasting operations. They are designed to efficiently capture and remove fine particles, dust, and contaminants from the air, ensuring a clean and healthy working environment. By utilizing cost-effective filtration systems, these air purifiers help to minimize operational costs while maintaining high air quality standards.

Overall, choosing air purifiers that offer both cost-effective solutions and noise reduction capabilities is essential for optimizing efficiency in sandblasting operations.

Understanding the Role of Pre-Filters in Sandblasting Air Purifiers

The role of pre-filters in sandblasting air purifiers is crucial for removing large particles before they reach the main filter. Pre-filters are designed to capture and trap larger particles such as dust, debris, and sand, which can clog the main filter and reduce its effectiveness.

There are several types of pre-filters available for sandblasting air purifiers, each with its own advantages and effectiveness. These include:

-

Pleated pre-filters: These pre-filters have a large surface area and are highly efficient in capturing and retaining large particles.

-

Foam pre-filters: These pre-filters are made of foam material that effectively traps and prevents large particles from entering the main filter.

-

Electrostatic pre-filters: These pre-filters use an electrostatic charge to attract and trap particles, preventing them from reaching the main filter.

-

Carbon pre-filters: These pre-filters are effective in removing odors and harmful gases, in addition to capturing large particles.

Overall, pre-filters play a vital role in maintaining the efficiency and longevity of sandblasting air purifiers by preventing large particles from clogging the main filter.

Maintenance and Cleaning Tips for Air Purifiers in Sandblasting Applications

To keep your air purifier in optimal condition, it’s important to regularly clean and maintain it in sandblasting applications. Proper maintenance and cleaning techniques will ensure that your air purifier continues to efficiently remove contaminants from the air, providing a safe and healthy working environment.

Here are some maintenance tips to follow:

- Check and clean the pre-filters regularly to prevent clogging and maintain optimal airflow.

- Replace the pre-filters when they become dirty or damaged.

- Clean the main HEPA filters by gently vacuuming or using compressed air to remove accumulated dust and debris.

- Inspect the seals and gaskets for any signs of wear or damage, and replace if necessary.

- Clean the exterior of the air purifier with a damp cloth or mild detergent to remove any surface dirt or grime.

Frequently Asked Questions

How Does Sandblasting Affect Air Quality?

Sandblasting can severely impact air quality due to the release of harmful particles into the atmosphere. To properly protect yourself during sandblasting, it is crucial to use appropriate respiratory equipment and ensure proper ventilation in the work area. Additionally, the environmental impact of sandblasting includes the potential contamination of soil and water sources.

Can Air Purifiers Completely Eliminate All Harmful Particles Generated During Sandblasting?

Air purifiers are effective in reducing sandblasting dust exposure, but they may not completely eliminate all harmful particles. Different types of air purifiers, such as HEPA filters and activated carbon filters, can be compared for sandblasting applications.

Are There Any Health Risks Associated With Breathing in Sandblasting Dust?

Breathing in sandblasting dust can pose serious health risks. To mitigate these dangers, it is crucial to use proper safety precautions and equipment, such as air purifiers, which provide health benefits by filtering harmful particles.

Can Air Purifiers Be Used in Outdoor Sandblasting Applications?

Yes, air purifiers can be used in outdoor sandblasting applications. They are beneficial as they help remove harmful dust particles from the air, ensuring a safer working environment for operators and reducing the risk of respiratory issues.

What Is the Expected Lifespan of an Air Purifier Used in Sandblasting?

The expected lifespan of an air purifier used in sandblasting depends on the maintenance requirements. How often it is cleaned and serviced can greatly impact its durability. Regular maintenance is crucial to ensuring optimal performance and longevity.

Conclusion

In conclusion, choosing the right air purifier for sandblasting is crucial in ensuring a safe and healthy working environment.

The ideal choice would be an air purifier equipped with HEPA filters, symbolizing the strength and efficiency needed to capture even the tiniest particles.

Additionally, the use of activated carbon filters represents the ability to enhance air quality by eliminating odors and chemicals.

Don’t forget the importance of pre-filters, which act as guardians, protecting the main filters from larger debris.

Remember to regularly maintain and clean your air purifier to ensure its continued effectiveness.