Electrostatic precipitators trap particulates by charging dust particles through ionization from high-voltage electrodes. These charged particles are then attracted to grounded collection plates by electric forces, where they adhere due to surface interactions. Regular maintenance guarantees effective adhesion and removal, preventing efficiency loss. Thanks to their design, they effectively capture fine and ultrafine particles while operating cost-effectively. To understand how design improvements and environmental factors influence performance, keep exploring this fascinating cleaning technology.

Key Takeaways

- Electrostatic precipitators generate an electric field that charges airborne particles, causing them to attract to collection plates.

- Discharge electrodes emit ions that transfer charge to particles via ionization, enhancing their electrostatic attraction.

- Charged particles move toward grounded collection plates under the influence of the electric field, where they adhere due to electrostatic forces.

- Surface properties and environmental conditions affect particle adhesion strength, ensuring particles stay attached for removal.

- Regular maintenance and cleaning prevent dust buildup, maintaining high efficiency in trapping particulates.

The Basic Components of Electrostatic Precipitators

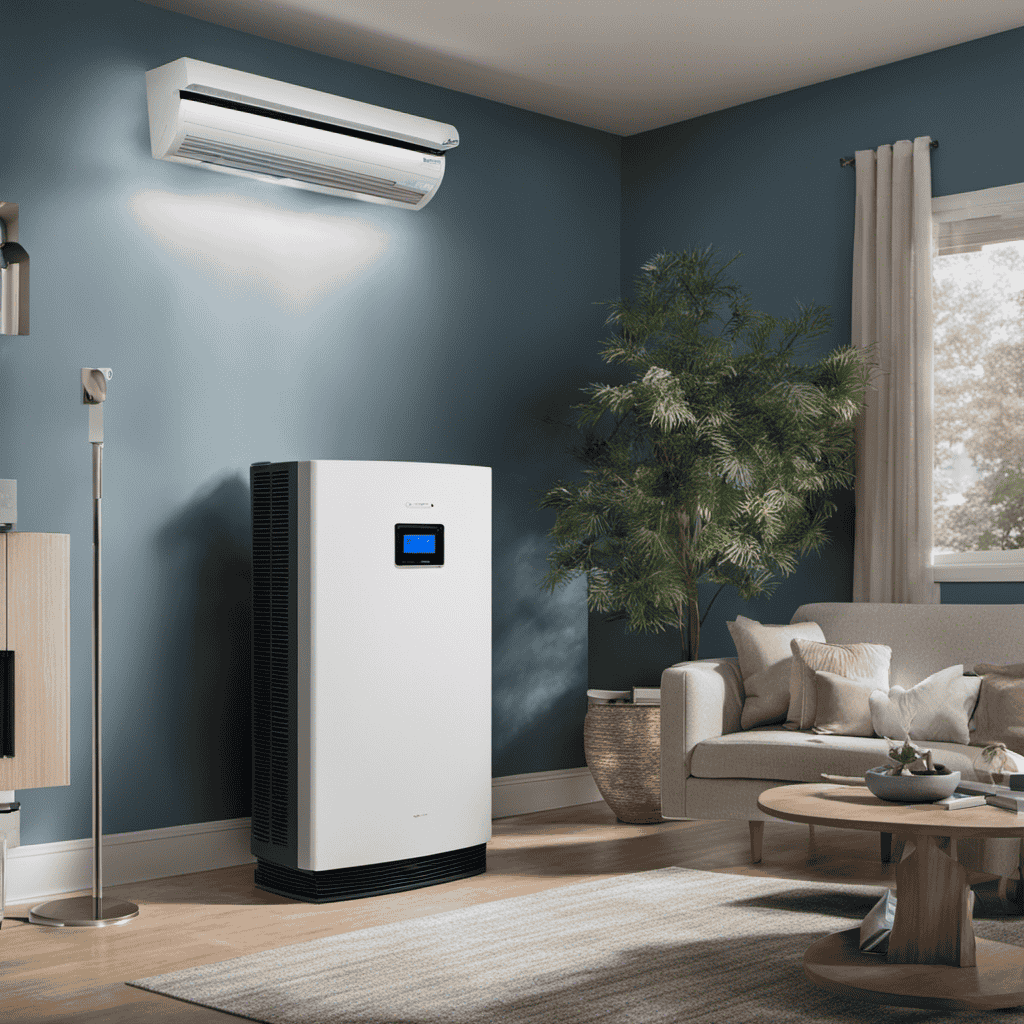

Electrostatic precipitators consist of several essential components that work together to remove particles from exhaust gases. The core is the electrostatic field, created by high-voltage electrodes that generate a strong electric charge. As the exhaust gases pass through, particles experience forces that influence their particle dynamics, causing them to move toward collection plates. The discharge electrodes emit ions that charge the particles, while the collection plates attract and hold the charged particles. A power supply maintains the electric field, ensuring continuous operation. Additionally, rapping mechanisms shake off accumulated dust, allowing it to be collected and removed. Understanding how the electrostatic field influences particle dynamics is key to optimizing each component’s role in capturing airborne pollutants effectively. The design of these components often incorporates advanced materials to enhance durability and performance. This integration of modern materials can also help improve energy efficiency in operation, reducing overall operating costs. Names inspired by famous personalities can also be used to personalize the equipment and improve its aesthetic appeal.

How Electric Charges Capture Particulates

The process of capturing particulates hinges on how electric charges influence particles within the precipitator. When particles pass through, they acquire a charge through charge transfer, either by contact or induction. This creates an electrostatic force between the charged particles and the grounded collection plates. This electrostatic force pulls the particles toward the plates, causing them to adhere. The stronger the charge on the particles, the more effective the attraction. As particles move closer, the charge transfer from the particles to the plates increases, strengthening their attachment. This method guarantees that particles are efficiently separated from the airflow, allowing cleaner air to exit. Understanding charge transfer is essential for optimizing the efficiency of electrostatic precipitators. Additionally, automation can be employed to monitor and adjust the charging process for improved performance. Proper maintenance and regular cleaning of the collection plates can also enhance precipitator efficiency over time. Incorporating real-time monitoring systems helps in maintaining optimal operational parameters and preventing performance drops.

The Process of Ionization and Charging of Particles

You can understand how particles become charged through the ionization mechanism, where high-voltage electrodes strip electrons from molecules or particles. As ions are generated, they create a charge that attaches to particles in the air. This charge accumulates over time, enabling the particles to be attracted to and collected on the oppositely charged plates. Environmental considerations are crucial to ensure the safe deployment of these systems and prevent potential vulnerabilities. Additionally, color accuracy in the design of these systems can influence the efficiency of particle collection and overall performance. Proper electrode maintenance is also essential to maintain optimal ionization efficiency and system longevity. Regular inspections help prevent performance degradation caused by dirt buildup or electrode wear, ensuring consistent operation.

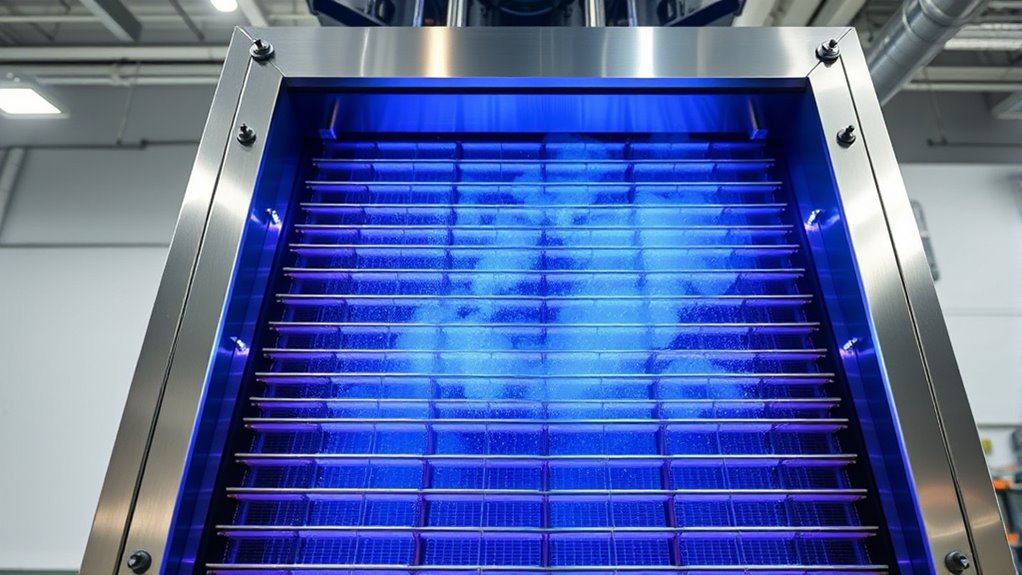

Particle Ionization Mechanism

Have you ever wondered how particles in an electrostatic precipitator become charged? It all starts with ionization, where high-voltage electrodes generate a corona discharge that creates ions. These ions collide with airborne particles, transferring a charge through the process of ionization. The efficiency of this process, known as ionization efficiency, determines how effectively particles acquire a charge. Once charged, particles develop a charge distribution, meaning some carry a stronger or weaker charge depending on factors like particle size and composition. This charge influences how particles move toward collection plates. A well-designed ionization mechanism ensures a uniform charge distribution, maximizing collection efficiency and reducing particle escape. Properly controlling the electric field within the precipitator can further enhance ionization and particle collection. Additionally, understanding the sound design techniques used in creating effective noise mitigation systems can help improve the overall environment around industrial equipment. Optimizing the ionization process is essential for achieving the highest collection efficiency and maintaining compliance with environmental standards. Incorporating essential oils in maintenance areas can help reduce airborne contaminants and improve air quality for workers. Moreover, maintaining proper electrode cleanliness is crucial for sustaining optimal ionization performance over time.

Charge Accumulation Process

In the charge accumulation process, particles in an electrostatic precipitator become charged through a series of rapid interactions with ions generated by the corona discharge. As ions collide with particles, they transfer charge, creating a charge distribution across the particle surface. Electrostatic induction can also influence this process, causing charge migration without direct contact. This dynamic results in particles with varying charge levels, optimizing their attraction to collection plates. The following table illustrates how different factors affect charge accumulation:

| Factor | Effect on Charge Distribution | Role of Electrostatic Induction |

|---|---|---|

| Particle size | Larger particles hold more charge | Induces charge in nearby particles |

| Ion density | Increases overall charge transfer | Enhances charge uniformity |

| Electric field strength | Accelerates ion-particle interactions | Promotes even charge distribution |

Additionally, the charge transfer process is essential for understanding how particulate matter is effectively captured in electrostatic precipitators. Understanding charge distribution can further improve the design and efficiency of these systems.

Collection Plates and Particle Removal

You’ll want to understand how the plates are charged to attract particles effectively. Once particles reach the plates, they stick through adhesion, allowing for removal. Maintaining the plates properly guarantees the system stays efficient and continues to operate at peak performance.

Plate Charging Mechanism

The plate charging mechanism in electrostatic precipitators relies on the application of a high-voltage electric field to create a strong electrostatic charge on the collection plates. When the field is applied, the plates undergo plate polarization, causing electrons to shift within the metal. This process induces a charge induction, generating an electrostatic field that attracts charged particles. As particles pass near the plates, they become polarized or gain a charge, making them easy to attract to the oppositely charged collection surfaces. The high voltage ensures a consistent, strong electric field, maximizing particle attraction. Additionally, the efficiency of this process can be influenced by factors such as airflow dynamics and particle size, which are critical for optimal performance. Understanding the patterns of behavior in particulate movement can help improve the design and operation of electrostatic precipitators. Furthermore, implementing maintenance practices can sustain the effectiveness of the charging system over time. Regular operation also benefits from monitoring the electrical parameters to ensure consistent charging efficiency. This mechanism efficiently captures particulates, preventing them from escaping into the environment, and prepares them for the subsequent removal process.

Particle Adhesion Process

Once particles have been charged and attracted to the collection plates, the next step involves ensuring they stick securely until removal. Particle adhesion depends on surface interactions between the particles and plates. Strong surface interactions promote better adhesion, preventing particles from re-entraining into the airflow. To understand this, consider the factors influencing adhesion:

| Factor | Effect |

|---|---|

| Surface roughness | Increases contact points, enhancing adhesion |

| Particle size | Larger particles tend to stick more effectively |

| Humidity | Moisture can strengthen surface interactions |

| Surface interactions | Play a crucial role in automation efficiencies within electrostatic precipitators. Surface properties can be optimized through material selection to improve overall collection performance. Incorporating surface treatments can further enhance particle adhesion by modifying surface energy properties, which can be tailored through coating techniques to achieve desired adhesion characteristics. Additionally, understanding the surface energy of both particles and plates can significantly influence adhesion effectiveness. |

Maintenance and Efficiency

Maintaining collection plates and ensuring effective particle removal are vital for the electrostatic precipitator’s peak performance. Regular electrostatic cleaning keeps the plates free of accumulated dust, preventing efficiency loss and prolonging the precipitator lifespan. If you neglect maintenance, particles can build up, creating a barrier that reduces the electric field’s effectiveness. This leads to decreased particle capture and increased pressure drops, forcing the system to work harder. Consistent inspection and timely cleaning of the plates ensure that particles are efficiently collected and removed. By staying on top of maintenance, you improve the precipitator’s overall efficiency, reduce energy costs, and extend its service life. Proper upkeep is essential for maintaining high performance and preventing costly downtime. Recognizing the importance of spiritual guidance can also help in understanding the significance of routine care and attention to detail in system maintenance.

Advantages of Using Electrostatic Precipitators

Electrostatic precipitators offer several key advantages that make them a popular choice for air pollution control. One major benefit is that they provide cost-effective solutions, especially over the long term, due to their low operational and maintenance costs. They also excel in removing fine and ultrafine particles, which many other filters struggle with. Additionally, electrostatic precipitators offer scalability options, allowing you to adapt them for small industrial plants or large power stations. Their ability to handle large volumes of air efficiently makes them versatile for various applications. Plus, they generate minimal waste, reducing disposal concerns. Overall, these features make electrostatic precipitators a reliable and economical choice for improving air quality in different settings.

Common Challenges and Maintenance Tips

While electrostatic precipitators are highly effective and economical, they do face some common challenges that you should know about. One issue is electrostatic wear, which occurs over time as components like collector plates and wires degrade due to constant electrical activity. Regular inspection and timely replacement help prevent efficiency drops. Ash buildup is another challenge; it can insulate collection surfaces, reducing effectiveness. To manage this, you should schedule routine cleaning to remove accumulated ash and prevent blockages. Additionally, monitoring the system’s electrical connections and ensuring proper grounding can minimize operational problems. Proper maintenance not only extends the lifespan of your precipitator but also ensures it continues trapping particulates efficiently. Staying proactive with these tips keeps your air purification system running smoothly.

Environmental Impact and Future Developments

Have you ever wondered how electrostatic precipitators impact the environment? They play a crucial role in improving air quality by reducing airborne pollutants, aiding pollution control efforts. Future developments aim to make these devices more efficient and eco-friendly. Imagine:

Electrostatic precipitators enhance air quality by reducing airborne pollutants and supporting pollution control efforts.

- Upgraded plates that capture more particles with less energy.

- Smarter systems that automatically adjust to pollution levels.

- Use of sustainable materials to reduce waste.

- Integration with renewable energy sources to lower carbon footprints.

These advancements will help reduce emissions further, making industries cleaner and communities healthier. As technology evolves, electrostatic precipitators will continue to be essential in minimizing environmental impact while supporting stricter pollution control standards. You, as a stakeholder, can expect cleaner air and a healthier planet ahead.

Frequently Asked Questions

How Effective Are Electrostatic Precipitators at Removing Ultrafine Particles?

You want to know how effective electrostatic precipitators are at removing ultrafine particles. They excel in ultrafine particle removal, especially for particles smaller than 0.1 micrometers, thanks to their high precipitator efficiency. While not perfect, they appreciably reduce airborne pollutants, making the air cleaner. Their ability to capture these tiny particles depends on factors like voltage and particle charge, but overall, they’re a highly effective solution for ultrafine particle removal.

What Industries Most Commonly Utilize Electrostatic Precipitator Technology?

You’ll find electrostatic precipitator technology most commonly in industries like manufacturing and power plants. They effectively control manufacturing emissions by trapping dust and particulate matter before they’re released into the atmosphere. Power plant filtration relies on these devices to reduce harmful pollutants, improving air quality. Their ability to handle large volumes of gases makes them essential for industries aiming to meet environmental standards and minimize their impact on the environment.

How Do Electrostatic Precipitators Compare to Other Air Purification Methods?

Ever wondered how electrostatic precipitators compare to alternative filtration methods? These devices excel in electrostatic efficiency, capturing fine particles with high effectiveness, especially in industrial settings. Unlike traditional filters, they don’t rely solely on physical barriers, making them more durable and easier to maintain. While HEPA filters excel at removing allergens, precipitators handle large volumes of industrial pollutants efficiently. Wouldn’t you want a solution that offers both high efficiency and low maintenance?

Are There Any Health Risks Associated With Electrostatic Precipitator Operation?

You might wonder if electrostatic precipitator operation poses health risks. While generally safe, there are occupational hazards to contemplate, like potential electrical shocks or exposure to chemicals used in maintenance. Proper safety measures, such as protective gear and regular inspections, reduce these risks. If you handle or work near these devices, staying aware of chemical exposure and following safety protocols helps protect your health.

What Innovations Are Emerging to Improve Electrostatic Precipitator Efficiency?

You’re exploring how electrostatic precipitator efficiency can enhance. Innovations like nanotechnology enhancements enable finer particulate capture, increasing overall effectiveness. Real-time monitoring systems let you track performance continuously, promptly detecting issues and optimizing operation. These advancements help you maintain cleaner air, reduce energy use, and extend equipment lifespan, making electrostatic precipitators more reliable and efficient. Staying updated on these innovations ensures you maximize pollution control and meet evolving environmental standards.

Conclusion

By understanding how electrostatic precipitators gently draw in airborne particles, you can appreciate their quiet contribution to cleaner air. With proper maintenance and awareness, you help guarantee these devices continue to work smoothly, quietly enhancing your environment. Embracing this technology means supporting a healthier, more sustainable future without much fuss. So, by choosing to keep your precipitator in good shape, you’re softly helping the world breathe a little easier every day.