To manage particulate matter and VOCs from laser cutting and engraving, you should use high-quality air filtration systems like HEPA filters for dust and activated carbon filters for fumes. Combine these with proper ventilation strategies, such as local exhaust hoods near your laser machines, to capture emissions at the source. Regular maintenance and monitoring guarantee your system remains effective. Keep exploring for more detailed tips on creating a safe workspace that protects your health.

Key Takeaways

- Install combined HEPA and activated carbon filters to effectively capture particulates and VOCs emitted during laser processes.

- Use local exhaust ventilation systems positioned close to the laser machine for direct removal of pollutants at the source.

- Regularly maintain and replace filters to ensure optimal filtration efficiency and consistent air quality.

- Monitor air quality with sensors to adjust ventilation and filtration systems proactively.

- Ensure proper workspace airflow and containment measures to minimize airborne contaminant exposure.

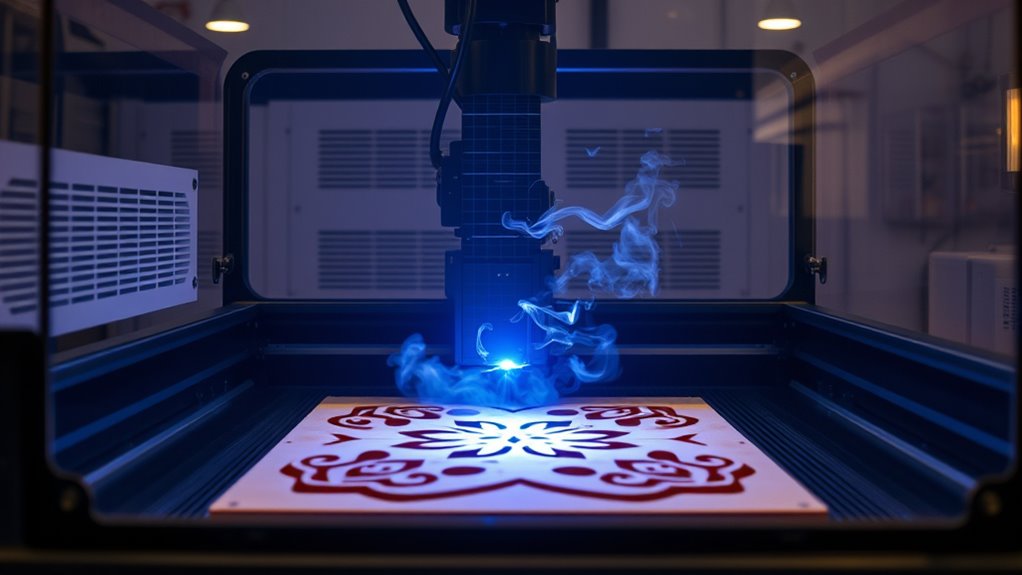

Laser cutting and engraving are efficient methods for creating detailed designs, but they also generate particulate matter and volatile organic compounds (VOCs) that can pose health risks. When you operate laser machines, airborne contaminants like dust, smoke, and chemical fumes are released into your workspace. Without proper controls, these emissions can lead to respiratory issues, eye irritation, or long-term health problems. That’s why managing these airborne hazards is essential to maintaining a safe environment.

Implementing effective air filtration is your first line of defense. High-quality air filters capture fine particles and VOCs before they disperse into the air, considerably reducing airborne contaminants. You should choose filtration systems equipped with HEPA filters for particulates and activated carbon filters for VOCs. These filters work together to clean the air, trapping small dust particles and chemical fumes, so you and your team don’t breathe in harmful substances. Regular maintenance and timely filter replacements ensure your filtration system remains effective, preventing buildup that can compromise air quality.

Effective air filtration with HEPA and activated carbon filters is essential for a healthier workspace.

Alongside air filtration, proper ventilation plays a critical role. Ventilation systems help move contaminated air out of your workspace and bring in fresh air, diluting the concentration of harmful emissions. You should design your ventilation setup to provide adequate airflow based on your laser cutter’s volume and the materials used. Local exhaust ventilation, such as fume extractors directly connected to the laser machine, is especially effective because it captures pollutants at the source before they spread. This minimizes the risk of airborne exposure and creates a safer environment.

You need to integrate these systems seamlessly into your workspace. Position exhaust hoods or ducting close to the laser cutter to maximize capture efficiency. Ensure your ventilation system is properly balanced; excessive airflow can cause discomfort or disturb delicate work, while insufficient airflow leaves contaminants lingering in the air. Use sensors or air quality monitors to regularly assess the effectiveness of your filtration and ventilation systems, making adjustments as needed. Keeping your workspace well-ventilated and filtered isn’t just about compliance — it’s about protecting your health and the health of anyone nearby. Additionally, understanding the types of emissions generated during laser operations can help tailor your filtration solutions more effectively.

Frequently Asked Questions

What Are the Long-Term Health Effects of VOC Exposure?

Exposure to VOCs over the long term can lead to serious health issues. You might develop chronic respiratory problems, such as asthma or bronchitis, and face increased risks of lung infections. Prolonged exposure could also cause headaches, dizziness, and even damage to your nervous system. To protect your health, guarantee proper ventilation and use protective equipment, minimizing your risk of long-term respiratory and chronic health effects from VOC exposure.

How Often Should Air Filtration Systems Be Maintained?

Think of your air quality like a garden that needs regular tending. You should replace filters every 3 to 6 months, depending on usage and manufacturer recommendations. Consistent maintenance ensures your air filtration system runs efficiently, reducing particulate and VOCs. Regular filter replacement keeps your workspace safe, prevents buildup, and maintains ideal air quality, so you can work confidently knowing you’re protecting your health and that of others.

Are There Eco-Friendly Alternatives to Traditional Filtering Methods?

Yes, you can opt for eco-friendly filtering alternatives. Biodegradable filters made from eco-conscious materials break down naturally, reducing environmental impact. These filters are effective at capturing particulates and VOCs while being sustainable. By choosing biodegradable options, you support environmentally responsible practices and decrease waste. Incorporate these eco-friendly filters into your system to maintain air quality without compromising your commitment to sustainability.

Can Laser Parameters Influence Particulate and VOC Emissions?

Did you know that optimizing laser parameters can reduce emissions by up to 50%? You can influence particulate and VOC emissions through laser parameter optimization, adjusting factors like power, speed, and focus. Implementing emission control techniques alongside these adjustments guarantees cleaner air. By fine-tuning your laser settings, you actively lower harmful emissions, making your process more eco-friendly and safer for everyone around you.

What Safety Equipment Is Recommended for Operators?

You should wear respirator masks and protective gloves when operating laser cutting and engraving equipment. Respirator masks help filter out harmful particulates and VOCs released during the process, while gloves protect your hands from hot surfaces and sharp edges. Always make certain your safety gear fits properly and is rated for chemical and particulate filtration. Using this equipment reduces health risks and keeps you safe during your work.

Conclusion

To keep your workspace safe, always use proper ventilation and filtration systems—think of it as your modern-day alchemy lab, but without the dragons. Regularly maintain your equipment to prevent buildup, and wear protective gear to shield yourself from harmful particulates and VOCs. Remember, even in these tech-savvy times, a little old-fashioned caution goes a long way. Stay vigilant, and you’ll master your craft without risking a trip to the underworld of fumes.