Graphene filters are a breakthrough in water purification, using ultra-thin, durable sheets of carbon that can remove contaminants at a molecular level. Their high electrical conductivity, chemical stability, and precisely engineered pores make them more efficient than traditional filters. These filters can target heavy metals, organic pollutants, and pathogens, offering a lightweight, scalable, and cost-effective solution. To find out how this innovative material could transform clean water access, keep exploring what makes graphene so revolutionary.

Key Takeaways

- Graphene filters are ultra-thin membranes capable of removing contaminants at the molecular level in water treatment.

- They are fabricated using techniques like chemical vapor deposition and reduction of graphene oxide for high quality.

- Customizable pore sizes enable targeted filtration of heavy metals, organic pollutants, or pathogens.

- These filters are lightweight, durable, chemically stable, and suitable for harsh environmental conditions.

- Advances in scalable manufacturing methods are making graphene-based filters more affordable and ready for widespread use.

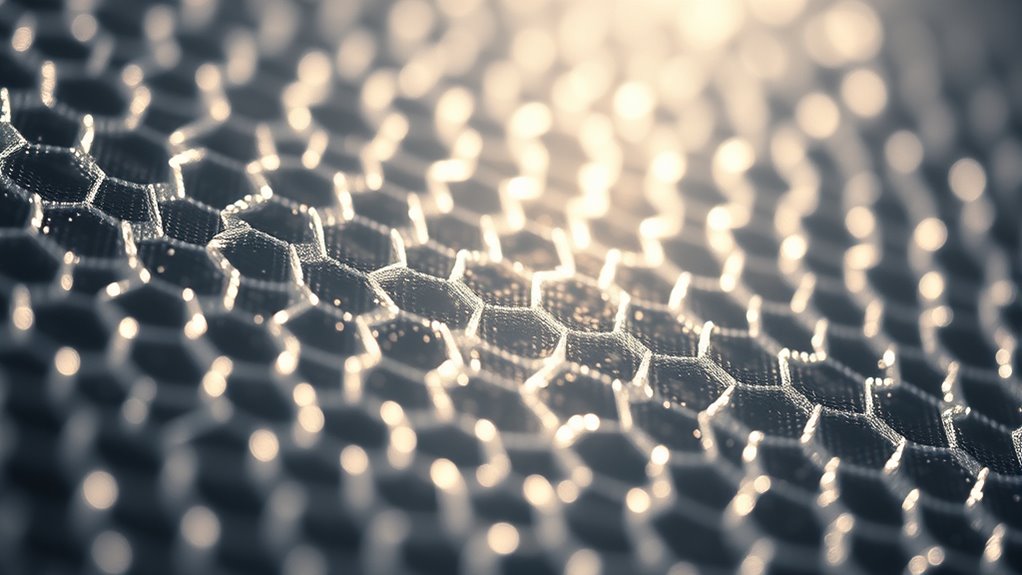

Have you ever wondered how advanced materials can revolutionize water filtration? The answer lies in the remarkable properties of nanomaterials, especially graphene. This one-atom-thick sheet of carbon atoms boasts exceptional strength, flexibility, and conductivity, making it a game-changer in filtration technology. Its nanomaterial properties enable it to filter out contaminants at a molecular level while maintaining durability and efficiency. But to harness these properties, scientists rely on sophisticated fabrication techniques. These methods allow precise control over the structure and quality of graphene filters, guaranteeing they perform at their best in real-world applications.

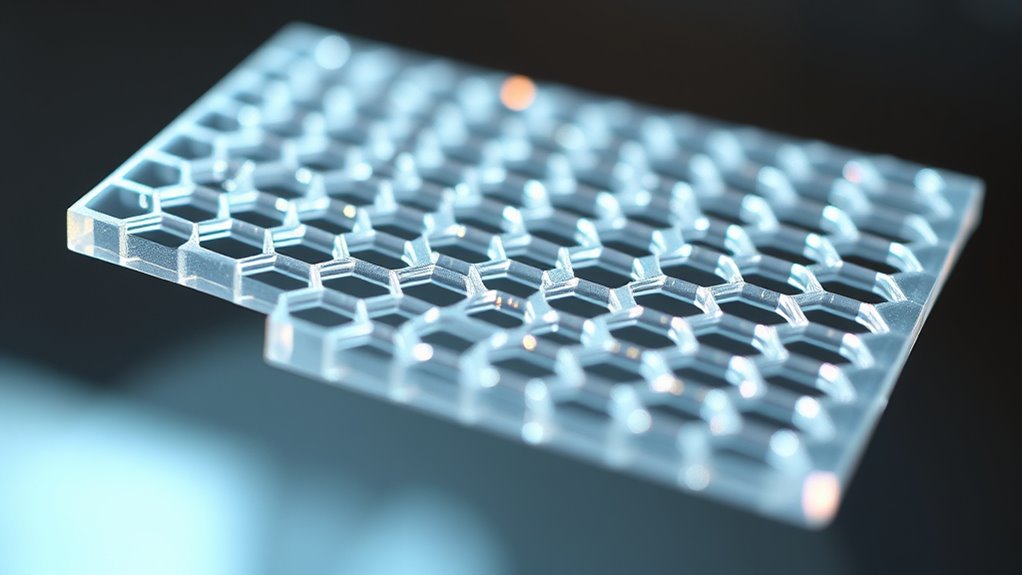

Fabrication techniques for graphene filters typically involve processes like chemical vapor deposition (CVD), which creates high-quality, large-area graphene sheets. CVD involves exposing a carbon-rich gas to a heated substrate, allowing carbon atoms to deposit and form a uniform graphene layer. This method ensures the production of defect-free sheets, vital for consistent filtration performance. Alternatively, other techniques such as exfoliation or reduction of graphene oxide are employed, each offering different advantages in terms of scalability and cost. Exfoliation involves peeling layers from graphite, producing smaller graphene flakes suitable for specialized applications. The reduction of graphene oxide involves chemically treating oxidized graphite to restore the graphene structure, creating a more affordable but slightly less pristine material.

Once fabricated, these graphene sheets can be engineered into membranes with controlled pore sizes. The size and distribution of these pores are critical because they determine which particles, bacteria, or chemical contaminants can pass through. Precise control over fabrication techniques allows you to customize these membranes for specific filtration needs, such as removing heavy metals, organic pollutants, or pathogens from water. Additionally, ongoing research into scalable production methods aims to make graphene filters more accessible and cost-effective for widespread use. The inherent nanomaterial properties of graphene, combined with advanced fabrication methods, make the resulting filters highly efficient, durable, and lightweight. They also exhibit excellent chemical stability, resisting degradation in harsh environments.

Moreover, ongoing innovations in fabrication techniques continue to improve the scalability and cost-effectiveness of graphene filters. Researchers are exploring new methods like roll-to-roll production and laser patterning to produce large quantities more efficiently. These advancements are essential for moving from laboratory prototypes to commercial applications, where affordability and reliability are key. As you consider the future of water filtration, understanding how the unique nanomaterial properties of graphene and the precision of fabrication techniques come together helps you appreciate the potential of this next-gen material. It’s not just about filtering water more effectively but transforming the entire approach to clean, safe water access worldwide.

Frequently Asked Questions

How Scalable Is Graphene Filter Production for Commercial Use?

You’re wondering how scalable graphene filter production is for commercial use. While manufacturing challenges exist, such as ensuring consistent quality and cost-effective methods, progress is being made. The supply chain is improving with new techniques and increased investment, making large-scale production more feasible. Although it’s not fully commercialized yet, ongoing research and development are promising, and widespread use could become a reality as these hurdles are overcome.

What Are the Long-Term Environmental Impacts of Graphene Filters?

You might wonder about the long-term environmental impacts of graphene filters. They could promote environmental sustainability by enabling cleaner water and air purification. However, their ecological footprint depends on production methods and disposal. If you use eco-friendly processes and recycle these filters properly, they could reduce waste and pollution over time. Careful management guarantees graphene filters support ecological health without harming the environment in the long run.

Can Graphene Filters Be Integrated With Existing Water Treatment Systems?

Think of integrating graphene filters into your existing water treatment systems as fitting a high-performance engine into a familiar car. You’ll find that their nanomaterial durability and superior filtration efficiency make upgrades smooth. These filters can be seamlessly added, enhancing performance without overhauling your setup. With their robustness, they promise long-lasting, effective purification, turning your water treatment into a cutting-edge operation while keeping operations cost-effective.

What Are the Cost Comparisons Between Graphene and Traditional Filters?

You’ll find that graphene filters offer better cost efficiency over traditional filters in the long run. Although manufacturing expenses for graphene are initially higher, their durability and superior filtration reduce replacement and maintenance costs. Over time, this makes graphene filters more economical, especially in large-scale water treatment. So, while the upfront investment might be greater, their efficiency and longevity can save you money overall.

How Do Graphene Filters Perform Against Emerging Pollutants?

Think of graphene filters as sharp-eyed guardians, ready to tackle emerging pollutants. You’ll find they excel in nanomaterial durability, maintaining performance over time, and show high pollutant specificity, targeting even the tiniest contaminants. Unlike traditional filters, they adapt quickly to new threats, offering superior filtration. You’ll appreciate how their advanced properties make them more effective for handling emerging pollutants, ensuring cleaner water and air for a healthier environment.

Conclusion

Imagine a future where your water is purified effortlessly with graphene filters. For instance, a city facing polluted water supplies could implement these filters, removing contaminants more efficiently than ever before. You’d enjoy cleaner, safer water daily, thanks to this cutting-edge material. Graphene filters aren’t just a breakthrough—they’re a game-changer that could transform how we access and secure our most crucial resource, making a healthier, more sustainable world within your reach.