Ionic ceramic filters are an emerging technology that use electrolyte enhancement and surface modification to boost air purification. By infusing ceramics with specific ions and creating rougher, functional surfaces, these filters attract and neutralize airborne pollutants like dust, bacteria, and VOCs more effectively. They also resist clogging and maintain performance longer. If you want to discover how these innovations can improve your air quality, keep exploring the details behind this promising breakthrough.

Key Takeaways

- Ionic ceramic filters utilize electrolyte enhancement and surface modification to improve pollutant capture and air purification efficiency.

- Electrolyte infusion boosts electrical properties, attracting charged particles like dust, bacteria, and allergens.

- Surface modifications increase active sites, enhancing filtration of tiny particles and reducing biofilm buildup.

- The combined technologies create a synergistic effect, extending filter lifespan and maintaining performance over time.

- Emerging advancements aim to make these filters more affordable, sustainable, and suitable for residential, commercial, and industrial applications.

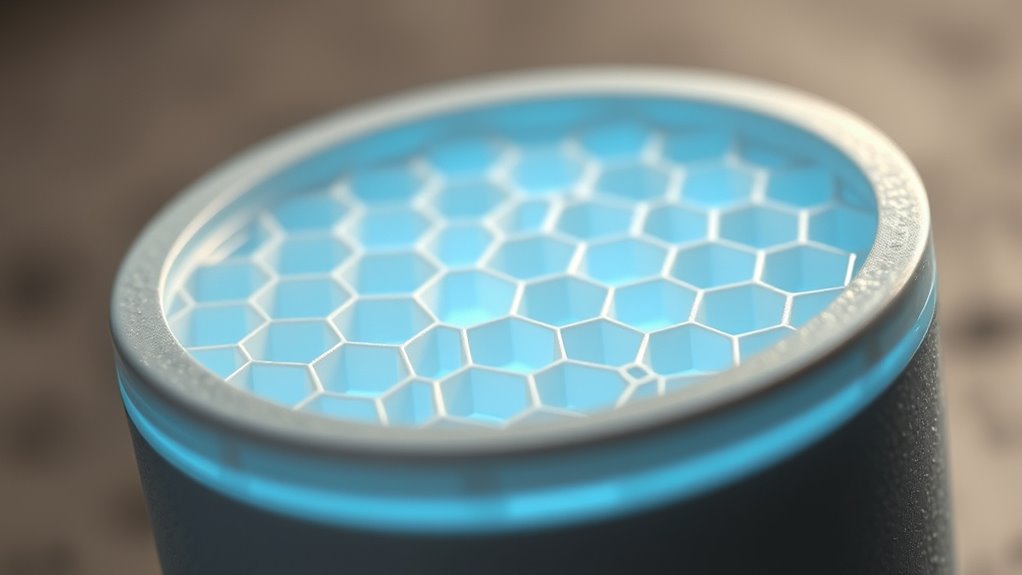

Are ionic ceramic filters the secret to cleaner air and more efficient filtration? These innovative devices are gaining attention because of their ability to trap pollutants more effectively than traditional filters. At the core of their advanced performance lies a combination of cutting-edge techniques, such as electrolyte enhancement and surface modification, which considerably boost their filtration capabilities. When you look closely, you’ll see that electrolyte enhancement involves infusing the ceramic material with specific ions, which improves its electrical properties. This process allows the filter to generate and maintain a steady ionic charge, attracting charged particles like dust, bacteria, and allergens more efficiently as air passes through. The enhanced electrolyte content fundamentally amplifies the filter’s ability to neutralize airborne contaminants, providing cleaner, healthier air in your environment.

Electrolyte enhancement boosts ionic charge, improving pollutant attraction and air purification efficiency.

Surface modification, on the other hand, plays a vital role in tailoring the ceramic surface for maximum performance. By altering the surface at a microscopic level, manufacturers can increase the number of active sites where pollutants can adhere. This might involve creating rougher textures or adding functional groups that attract specific particles, making the filter more selective and effective. When you use an ionic ceramic filter with these surface modifications, you notice a marked improvement in filtration efficiency, especially for tiny particles that traditional filters often miss. Plus, these modifications can reduce the buildup of dirt and biofilms on the filter surface, which helps maintain its effectiveness over time and minimizes maintenance needs.

Additionally, integrating remote hackathons into research and development processes can accelerate innovation in this field by enabling collaboration among global experts and sharing breakthroughs quickly.

Together, electrolyte enhancement and surface modification work synergistically to elevate the filter’s ability to purify air. You’ll find that these technologies enable the ceramic filters to actively attract and neutralize a broader spectrum of pollutants, including volatile organic compounds (VOCs), bacteria, and viruses. This not only results in cleaner air but also prolongs the lifespan of the filter because it resists clogging and degradation. The ionic charge created by electrolyte enhancement ensures that particles are captured more securely, while surface modification provides a more hospitable environment for trapping pollutants.

If you’re seeking a sustainable, high-performance filtration solution, ionic ceramic filters equipped with these emerging technologies offer a promising route. They combine scientific innovation with practical benefits, making your indoor air safer and healthier. As research progresses and manufacturing techniques improve, expect these filters to become even more effective, affordable, and widely adopted in residential, commercial, and industrial settings. Ultimately, understanding how electrolyte enhancement and surface modification work together can help you make informed choices when upgrading your air purification systems.

Frequently Asked Questions

How Do Ionic Ceramic Filters Compare to Traditional Filtration Methods?

You’ll find ionic ceramic filters more effective than traditional methods because they enhance nanoparticle efficiency, capturing smaller particles with greater precision. Plus, their material durability guarantees they last longer and withstand harsh conditions better. Unlike conventional filters, these emerging technologies use ionic properties to improve filtration performance, making them ideal for cleaner air and water. Overall, ionic ceramic filters offer superior efficiency and durability, making them a valuable upgrade in filtration systems.

What Industries Are Most Likely to Adopt Ionic Ceramic Filter Technology?

You’ll find ionic ceramic filter technology most likely adopted in industries like water treatment, where they enhance filtration efficiency for industrial applications. Medical innovations also benefit, as these filters can provide superior sterilization and contamination control. Their ability to target specific particles makes them ideal for sensitive environments. Overall, sectors prioritizing advanced filtration, safety, and purity will lead the charge in adopting this emerging technology.

Are Ionic Ceramic Filters Environmentally Sustainable?

You might think ionic ceramic filters are the ultimate eco-solution, but their environmental impact isn’t entirely negligible. While they promote resource efficiency by reducing waste and energy use, manufacturing and disposal can pose environmental challenges. Still, their potential to clean air and water with minimal ongoing resource consumption makes them a promising, if not perfect, step toward sustainability. They definitely contribute positively, but balance is key.

What Are the Main Challenges in Commercializing Ionic Ceramic Filters?

You’ll face scalability hurdles and material durability issues when commercializing ionic ceramic filters. Scaling up production can be complex and costly, limiting widespread adoption. Additionally, maintaining the filters’ durability over time is challenging, as they may degrade with continuous use or exposure to harsh environments. Overcoming these hurdles requires innovative manufacturing techniques and robust materials, but doing so is essential for successful market integration.

How Cost-Effective Are Ionic Ceramic Filters for Large-Scale Applications?

You might think ionic ceramic filters are too expensive for large-scale use, but their cost analysis often shows promising economic viability in the long run. While initial investments can be higher, their durability and efficiency reduce maintenance and operational costs. When considering mass deployment, these filters can be cost-effective, especially when factoring in environmental benefits and improved air quality, making them a viable option for extensive applications.

Conclusion

Imagine a world where your water is 99.9% free of harmful contaminants, thanks to ionic ceramic filters. These emerging technologies are revolutionizing filtration, providing safer, cleaner water for millions. With their ability to remove pollutants at the molecular level, you can trust they’re making a real difference. As their adoption grows, consider that by 2030, the market for ceramic filters is projected to hit $2 billion—proof of their rising importance in safeguarding your health.