To keep your auto and motorcycle workshop safe, you need effective air purification systems. Use high-quality air filters, such as HEPA filters, to trap dust and fine particles. Combine local exhaust hoods and extractor fans near painting or welding areas to capture fumes at the source. Regular maintenance of these systems guarantees they work efficiently. Implementing these measures helps protect your team and ensures compliance—discover more ways to create a healthier workspace as you continue.

Key Takeaways

- Implement local exhaust ventilation systems near painting, welding, and engine areas to capture fumes at their source.

- Use HEPA air purifiers to trap fine particulate matter and improve overall air quality.

- Regularly maintain and inspect ventilation equipment to ensure optimal performance and safety compliance.

- Combine extraction fans, hoods, and air filtration units for comprehensive air purification in the workshop.

- Educate staff on proper ventilation practices and ensure adherence to safety regulations to minimize health risks.

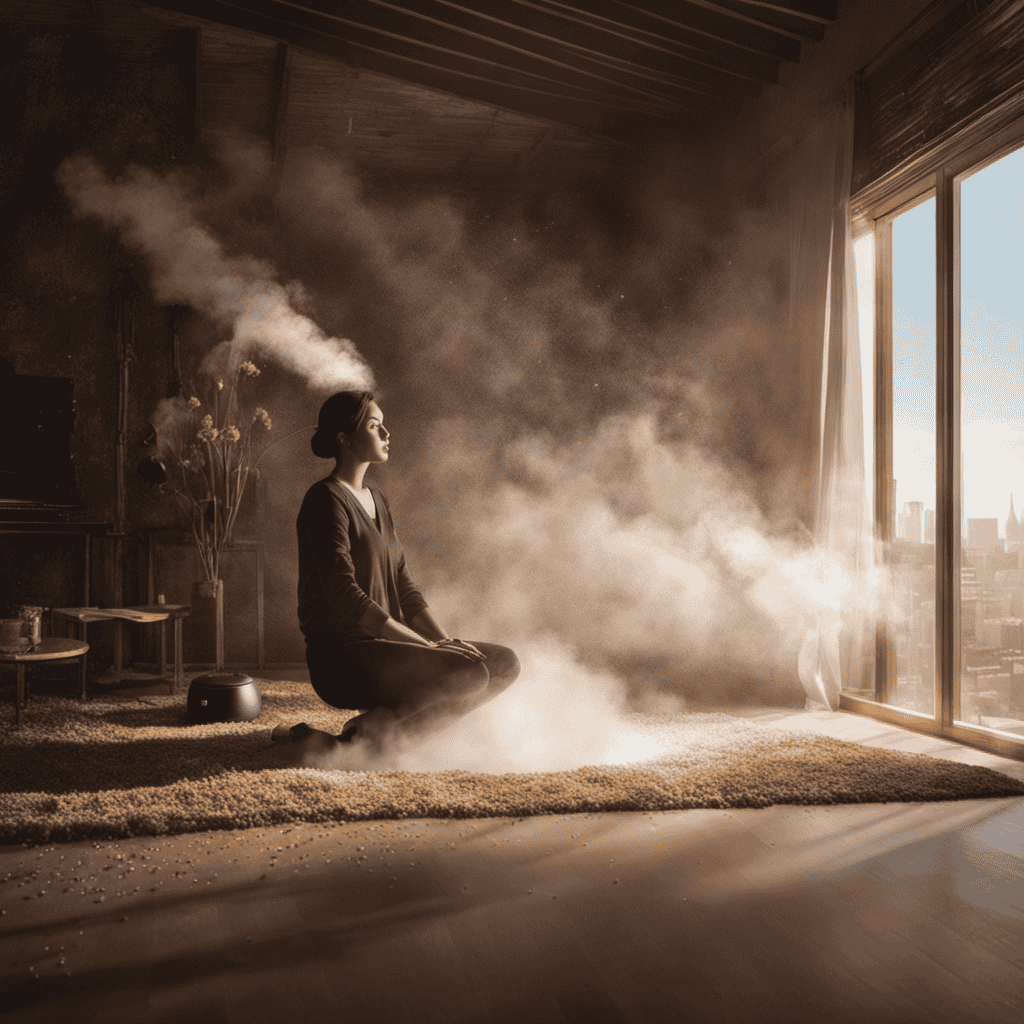

Auto and motorcycle workshops generate a variety of airborne pollutants, including paint fumes, exhaust gases, and particulate matter, which can pose serious health risks to workers. These hazardous fumes can cause respiratory problems, eye irritation, and long-term health issues if not properly managed. To protect yourself and your team, investing in effective ventilation systems is essential. Proper ventilation helps remove hazardous fumes from the workspace, maintaining safer air quality and reducing the risk of inhalation of dangerous substances. Without adequate ventilation, these fumes linger in the air, exposing everyone inside to potential harm. By installing a well-designed ventilation system, you ensure a steady flow of fresh air into the workshop and the removal of contaminated air, creating a healthier environment.

Proper ventilation is essential to remove hazardous fumes and ensure a safe, healthy workshop environment.

Ventilation systems are not just about comfort—they’re a critical safety feature. They can be tailored to the specific needs of your workshop, whether you’re working with spray paints, welding fumes, or engine exhaust. Extractor fans, local exhaust hoods, and air filtration units work together to capture and eliminate hazardous fumes at their source. For example, installing localized extraction points near paint booths or welding stations can prevent fumes from dispersing throughout the workspace. This targeted approach minimizes the overall pollutant load in the air, safeguarding your respiratory health and that of your colleagues.

It’s important to remember that not all ventilation systems are created equal. Proper maintenance and regular inspections are essential to ensure they operate efficiently. Clogged filters or malfunctioning fans can reduce their effectiveness, allowing hazardous fumes to accumulate. You should also consider integrating air purifiers equipped with HEPA filters to further enhance air quality by trapping fine particulate matter that traditional ventilation might miss. Combining these systems creates a multi-layered defense against airborne pollutants, providing a safer, healthier environment for everyone working in your workshop. Additionally, understanding the 16PF personality traits of your team can help tailor safety training and communication strategies to improve compliance and safety culture.

Furthermore, adhering to local safety regulations and standards regarding air quality and ventilation can help you avoid penalties and ensure compliance. Educate your staff on the importance of ventilation and proper equipment use. Encourage good practices, such as keeping ventilation in good condition and reporting any issues promptly. Remember, the goal is to proactively manage hazardous fumes before they pose a real threat to health. By prioritizing quality ventilation systems, you’re taking a crucial step toward a safer workshop environment, protecting your team from the dangers lurking in airborne pollutants, and ensuring your workspace remains compliant and healthy.

Frequently Asked Questions

How Often Should Air Purifiers Be Replaced in Workshops?

You should replace your air purifier filters every 6 to 12 months, depending on usage and filter lifespan. Regularly check the filters for dirt and wear, as a clogged filter reduces efficiency. The replacement frequency varies with workshop conditions—more contaminants mean sooner replacements. To guarantee ideal air quality, follow the manufacturer’s recommendations and inspect filters monthly, replacing them promptly when they show signs of heavy dirt or damage.

Are There Specific Air Purifiers for Different Workshop Sizes?

Choosing the right air purifier for your workshop is like finding a tailored suit—size matters. Yes, there are specific air purifiers designed for different workshop sizes to meet safety and air quality standards. Larger spaces need more powerful units, while smaller areas require compact models. By selecting the correct purifier, you enhance workshop safety and maintain ideal air quality, ensuring a healthier environment for everyone working there.

Can Air Purifiers Remove All Types of Automotive Fumes?

Air purifiers can substantially reduce automotive smoke and VOCs, but they might not eliminate every single type of fume. You should look for models with specialized filters for automotive smoke and VOC filtration to guarantee better results. Keep in mind, multiple filters or supplemental ventilation might be necessary for thorough air quality management in your workshop. Always choose an air purifier designed specifically for automotive fumes to maximize protection.

Do Air Purifiers Require Special Maintenance or Filters?

Air purifiers do require regular maintenance, but it’s straightforward. You’ll need to follow specific maintenance schedules, which often involve filter replacement. Unlike simple devices, these purifiers use specialized filters that trap automotive fumes and particulates; neglecting them can reduce efficiency. Keep an eye on the manufacturer’s guidelines, and replace filters as recommended to make certain your purifier continues to perform effectively and keeps your workshop air clean.

Are There Eco-Friendly Air Purification Options Available?

Yes, eco-friendly air purification options are available. You can choose models with eco-friendly filters made from sustainable materials, reducing environmental impact. Look for units that prioritize sustainable purification methods, such as activated carbon filters derived from natural sources or UV-C sterilization that minimizes chemical use. These options help you maintain clean air while supporting sustainability, making your workshop more eco-conscious without sacrificing air quality.

Conclusion

By implementing effective air purification, you protect your premises, people, and products. Prioritize proper placement, regular maintenance, and powerful filtration to keep pollutants at bay. Breathe better, boost business, and build a safer space. Don’t delay—delve into diligent diligence and discover the difference clean air makes. Your workshop’s wellness wins when you work with wisdom and worry less about airborne hazards. Make clean air your priority, and watch your workshop thrive with freshness and freedom.