As I delve into the intricacies of producing an air purifier, I discover the concealed expenses that influence its development.

From raw materials to labor and production, each element plays a crucial role in determining the final price tag.

With meticulous research and development expenses, coupled with overhead and operational costs, the true value of an air purifier comes to light.

Join me on this journey as we unravel the intricate web of pricing and profit margins in the world of air purification.

Key Takeaways

- The cost of manufacturing an air purifier is influenced by factors such as the complexity of design, materials used, and production techniques employed.

- Cost components in manufacturing an air purifier include the cost of raw materials, labor and production costs, research and development expenses, and overhead and operational costs.

- Pricing considerations for manufacturing an air purifier involve analyzing the impact on pricing, implementing efficiency and cost-saving measures, and maximizing profit margins.

- A data-driven approach, quality control measures, and competitor analysis are essential for manufacturing an air purifier and remaining competitive in the market.

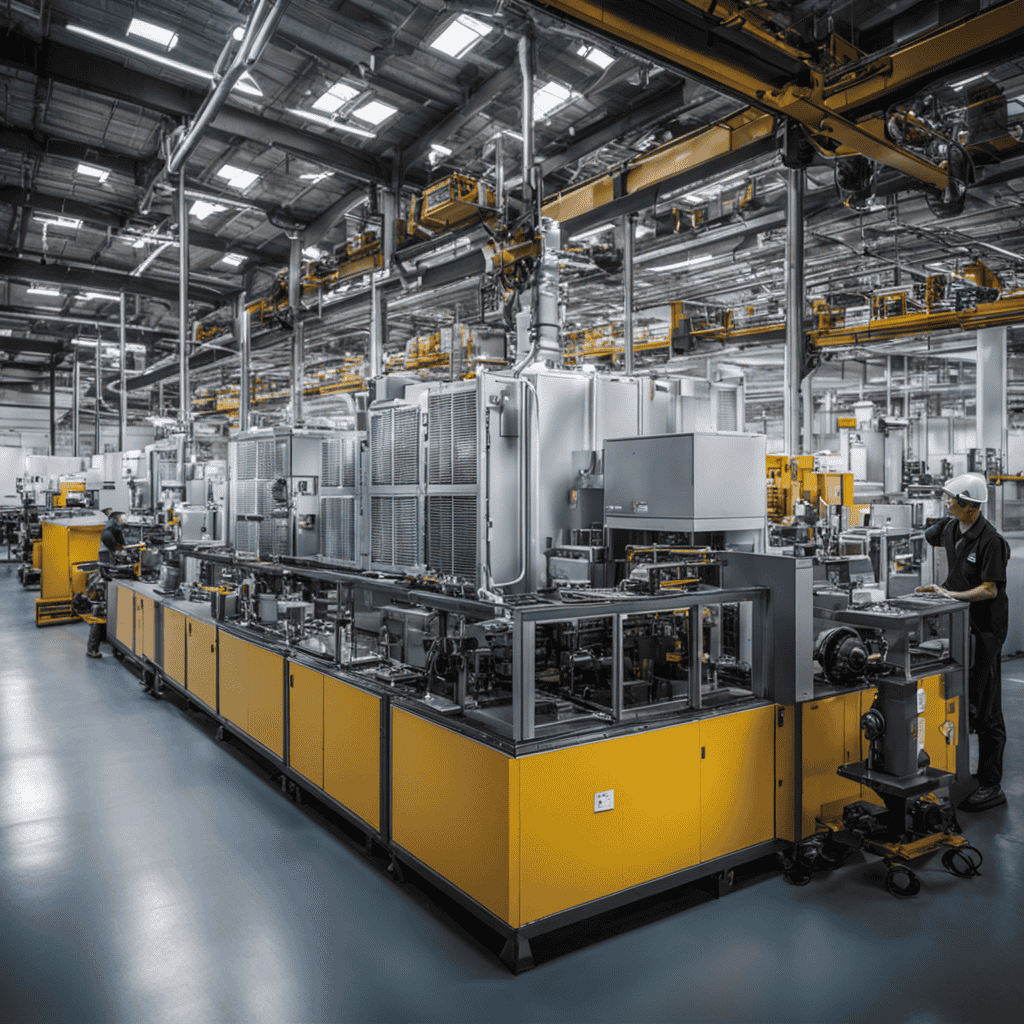

Factors Affecting Manufacturing Costs

You need to consider several factors when it comes to manufacturing costs for an air purifier.

The manufacturing process plays a significant role in determining the overall cost. The complexity of the design, the materials used, and the production techniques employed all contribute to the final price.

Cost optimization is crucial in this phase to ensure efficient resource allocation and minimize expenses. By streamlining the manufacturing process, eliminating redundant steps, and adopting lean manufacturing principles, costs can be reduced.

Additionally, selecting cost-effective materials without compromising quality is essential. Suppliers with competitive pricing can help in achieving this.

Furthermore, investing in automation and advanced machinery can increase productivity and reduce labor costs.

Overall, careful consideration of these factors can help in optimizing the manufacturing costs of an air purifier.

Cost of Raw Materials

The raw material expenses for producing an air purifier can vary depending on the type and quality of materials used. In addition to the cost of the materials themselves, there are other factors to consider that can impact the overall cost of production.

One such factor is the cost of transportation. This includes the cost of shipping the raw materials to the manufacturing facility and the cost of transporting the finished product to the customers.

Another factor to consider is the cost of packaging. This includes the cost of the materials used for packaging, such as boxes or plastic wrap, as well as the cost of labeling and branding the product.

These additional costs can significantly impact the overall cost of manufacturing an air purifier.

Labor and Production Costs

Labor and production costs can vary depending on factors such as wages, efficiency, and the complexity of the manufacturing process. When it comes to manufacturing an air purifier, labor productivity plays a crucial role in determining the overall cost. By increasing labor productivity, the amount of time and effort required to produce each unit can be reduced, resulting in lower labor costs.

Automation implementation is another key factor that can impact labor and production costs. By automating certain tasks, manufacturers can streamline the production process, improve efficiency, and reduce the need for manual labor. This not only cuts down on labor expenses but also minimizes the chances of errors or defects.

Moving forward, it is important to consider both labor productivity and automation implementation in order to optimize manufacturing costs and enhance profitability.

This brings us to the next important aspect of manufacturing expenses, research and development expenses.

Research and Development Expenses

When it comes to research and development expenses, it’s essential to allocate sufficient funds to ensure innovation and product improvement. Research and development investment plays a crucial role in the success of any business, especially in the manufacturing industry.

By investing in research and development, companies can stay ahead of the competition and bring new and improved products to the market. However, it’s also important to implement cost optimization strategies to maximize the return on investment. This includes conducting thorough market research, streamlining the product development process, and identifying areas where costs can be reduced without compromising quality.

By finding the right balance between investment and cost optimization, companies can achieve their research and development goals while maintaining financial stability.

Transitioning to the next section, overhead and operational costs play a significant role in the overall cost of manufacturing an air purifier.

Overhead and Operational Costs

As I delve into the topic of overhead and operational costs, I will be discussing the production cost breakdown and its impact on pricing. I will also explore the various efficiency and cost-saving measures that can be implemented.

In order to gain a comprehensive understanding of these key points, it is essential to analyze the data and examine the technical aspects of the manufacturing process. By examining the breakdown of production costs, we can identify areas of potential savings and efficiency improvements.

These improvements can have a significant impact on pricing strategies and overall profitability.

Production Cost Breakdown

To get a clear picture of the production cost breakdown of an air purifier, you should consider factors such as materials, electricity, and packaging. Conducting a thorough cost analysis is crucial in developing an effective pricing strategy for this product.

In terms of materials, the main components of an air purifier include the filter, casing, fan, and electronic components. These materials can vary in cost depending on their quality and specifications.

Additionally, electricity usage is an important consideration as air purifiers typically run continuously. The power consumption of the device must be factored into the overall production cost.

Lastly, packaging materials and design play a role in the production cost breakdown. Balancing these factors is essential in determining an optimal pricing strategy for air purifiers in the competitive market.

Impact on Pricing

Now that we have a clear understanding of the production cost breakdown for manufacturing an air purifier, let’s delve into the impact these costs have on pricing.

Conducting a pricing analysis is crucial to determine the optimal price point that maximizes profitability while remaining competitive in the market.

To do this, we need to consider various factors, such as market demand and the perceived value of the product.

By analyzing the market demand, we can identify the price elasticity and determine the price sensitivity of potential customers.

This data-driven approach allows us to optimize pricing strategies, such as setting a premium price for a high-demand product or offering competitive pricing to capture a larger market share.

Therefore, a thorough pricing analysis is essential to ensure that our air purifiers are priced accurately and attractively in the market.

Efficiency and Cost-Saving Measures

By implementing efficiency and cost-saving measures, I can significantly reduce production expenses for the air purifiers.

One crucial area to focus on is energy consumption. By using energy-efficient components and optimizing the design to minimize power requirements, I can reduce the overall energy consumption of the air purifiers, resulting in lower production costs.

Additionally, implementing effective quality control measures can help identify and rectify any manufacturing defects early on, reducing the need for rework or replacement of faulty components. This not only improves the overall quality of the air purifiers but also saves valuable resources and reduces production expenses.

Pricing and Profit Margins

When it comes to pricing and profit margins, there are several key factors that need to be taken into consideration.

First, it’s important to analyze the factors affecting pricing, such as production costs, market demand, and competition.

Next, maximizing profit margins requires a careful balance between pricing your product competitively and ensuring that your costs are covered.

Lastly, conducting a competitor price analysis can provide valuable insights into the market landscape and help inform your pricing strategy.

Factors Affecting Pricing

To determine the cost of manufacturing an air purifier, you need to consider various factors that affect pricing.

One of the key factors is market demand. The level of demand for air purifiers can have a significant impact on their manufacturing costs. When the demand is high, manufacturers may need to invest in additional production capacity, which can increase costs. On the other hand, when the demand is low, manufacturers may need to reduce their production volumes, which can also impact costs.

Another factor to consider is supply chain efficiency. The efficiency of the supply chain can affect both the cost of raw materials and the cost of transporting them to the manufacturing facility. By optimizing the supply chain, manufacturers can reduce costs and ultimately offer more competitive pricing to consumers.

Maximizing Profit Margins

Another factor that contributes to maximizing profit margins is the efficiency of the manufacturing process. In order to achieve high levels of efficiency, it is crucial to streamline all aspects of production, from sourcing raw materials to assembling the final product.

By implementing lean manufacturing principles and adopting advanced technologies, we can minimize waste and reduce production costs. This not only increases our profit margins, but also allows us to offer competitive prices to our customers.

Additionally, a highly efficient manufacturing process enables us to respond quickly to market demand. By producing air purifiers in a timely manner, we can meet customer expectations and enhance customer satisfaction.

Overall, the efficiency of our manufacturing process plays a vital role in maximizing profit margins while meeting market demand and ensuring customer satisfaction.

Competitor Price Analysis

Our team has conducted a competitor price analysis to determine how our prices compare to other companies in the market. Through this analysis, we have gained valuable insights into the pricing strategies employed by our competitors.

By comparing our prices to those of our competitors, we are able to identify any potential gaps or opportunities in the market. We have analyzed various factors such as product features, quality, and customer value to ensure an accurate comparison.

This data-driven approach allows us to make informed decisions about our pricing strategy and positioning in the market. By understanding how our competitors price their products, we can better assess our own pricing strategy and make adjustments as needed to remain competitive in the market.

Frequently Asked Questions

How Long Does It Take to Manufacture an Air Purifier?

It takes approximately 2 hours to manufacture an air purifier. The cost varies depending on factors such as the quality of materials used and the impact of technology incorporated into the manufacturing process.

Are There Any Environmental Regulations or Certifications That Impact the Manufacturing Cost?

Environmental regulations and certification costs can significantly impact the manufacturing cost of air purifiers. Compliance with regulations and obtaining certifications requires additional resources and investments, which can ultimately affect the overall cost of production.

What Is the Typical Lifespan of an Air Purifier and Does It Affect the Manufacturing Cost?

The typical lifespan of an air purifier depends on various factors, such as air quality and maintenance. These factors can impact the overall cost of owning an air purifier due to potential repairs or replacements.

Are There Any Specific Safety Standards That Manufacturers Need to Adhere to During the Production Process?

Safety standards are crucial in the production process of air purifiers. Manufacturers must adhere to specific guidelines to ensure the safety of users. These standards cover aspects such as electrical safety, emission levels, and filtration efficiency.

How Does the Size and Weight of an Air Purifier Affect Its Manufacturing Cost?

The size and weight of an air purifier can significantly impact its manufacturing cost. Design features such as compactness and lightweight materials can reduce production expenses, while larger and heavier units may require more resources and increase costs.

Conclusion

In conclusion, after considering all the factors discussed, it is evident that manufacturing an air purifier involves a combination of various costs.

From the raw materials to labor and production costs, research and development expenses, and overhead and operational costs, each aspect contributes to the final manufacturing cost.

The pricing and profit margins are crucial in determining the success of a product. Just like a delicate balancing act, manufacturers must carefully navigate these costs to ensure a profitable and efficient production process.