I understand your concern: the idea of constructing an industrial air purifier may seem overwhelming. However, I can assure you that it’s not as difficult as it may appear. In this article, I will walk you through the process step by step.

- Selecting the right components

- Understanding air filtration systems

- Designing an efficient circulation system

- Building the housing

- Installing and wiring the purification mechanism

By the end, you’ll have a fully functional air purifier that meets your industrial needs.

So let’s get started!

Key Takeaways

- Select air purifier components designed for industrial needs

- Regularly clean or replace filters for optimal performance

- Properly design ductwork to minimize air resistance

- Position the fan strategically to maximize airflow

Selecting the Right Air Purifier Components

When selecting the right air purifier components, it’s important to consider the size and efficiency of the filters.

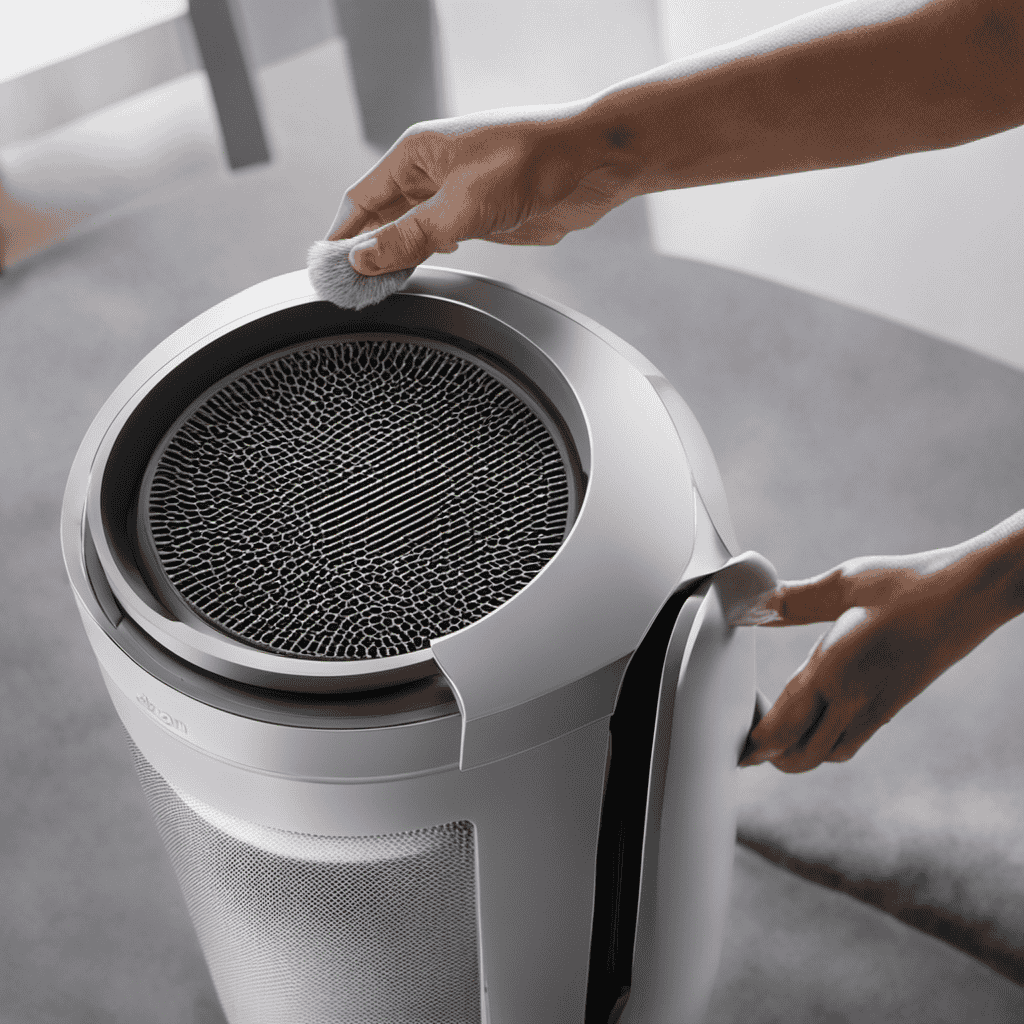

Air purifier maintenance is crucial for optimal performance and longevity of the device. Regularly cleaning or replacing the filters ensures that the air purifier continues to effectively remove contaminants from the air. It is recommended to check the manufacturer’s instructions for specific maintenance guidelines.

Another important factor to consider is the noise level of the air purifier. Some models produce a significant amount of noise, which can be disruptive in certain environments. By choosing components that are designed to minimize noise, such as quieter fans and sound-dampening materials, you can create a more comfortable and peaceful environment while still enjoying the benefits of clean air.

Understanding Air Filtration Systems

When it comes to understanding air filtration systems, it’s essential to familiarize ourselves with the key filtration components and how to choose the right system.

The key filtration components include the pre-filter, carbon filter, HEPA filter, and UV-C light. Each component plays a crucial role in removing different types of contaminants from the air, ensuring a cleaner and healthier environment.

In order to select the right system, factors such as the size of the space, the specific pollutants present, and the desired level of filtration efficiency must be taken into consideration.

Key Filtration Components

To build an industrial air purifier, you’ll need key filtration components such as activated carbon filters and HEPA filters.

Air purifier filters play a crucial role in the purification technology by removing harmful particles and pollutants from the air.

Activated carbon filters are highly effective in eliminating odors, gases, and volatile organic compounds (VOCs) by adsorbing them onto the carbon surface.

HEPA filters, on the other hand, capture and trap particles as small as 0.3 microns, including dust, pollen, pet dander, and mold spores.

These filters work together to provide a comprehensive air purification system that ensures clean and healthy air in industrial settings.

Now that we understand the importance of key filtration components, let’s move on to the next step of choosing the right system.

Choosing the Right System

If you’re looking to choose the right system, consider factors such as the size of the space and the specific air purification needs of your industrial setting.

Air purifier technology advancements have made it easier than ever to maintain these systems and ensure optimal performance. Regular air purifier maintenance is crucial to keep the system running efficiently and effectively.

This includes cleaning or replacing filters, checking and cleaning the fan blades, and inspecting the electrical components for any signs of wear or damage. By staying on top of maintenance tasks, you can extend the lifespan of your air purifier and improve its overall performance.

With advancements in technology, modern air purifiers are equipped with features such as air quality sensors and automatic filter replacement indicators, making maintenance even more convenient.

Now, let’s explore the next step in designing an efficient air circulation system.

Designing an Efficient Air Circulation System

An efficient air circulation system is essential for the design of an industrial air purifier. It ensures proper airflow, which is crucial for optimizing filter effectiveness and maintaining a clean and healthy environment.

To achieve this, the following elements should be considered:

- Powerful Fans: High-performance fans are required to move large volumes of air efficiently.

- Ductwork Design: Properly designed ductwork minimizes air resistance and ensures even distribution of purified air.

- Airflow Direction: The system should be designed to create a unidirectional airflow, preventing the re-entrainment of pollutants.

- Filter Placement: Filters should be strategically placed to maximize their effectiveness and ensure easy maintenance.

- Variable Speed Control: Incorporating variable speed control allows for adjusting the fan speed based on the air quality requirements.

Building the Air Purifier Housing

When it comes to building the housing for an air purifier, there are several key points to consider.

First, material selection is crucial in ensuring the durability and effectiveness of the housing. I will provide some tips on choosing the right materials based on their compatibility with the air purification system.

Secondly, assembling the housing step-by-step is essential for a successful construction process. I will guide you through the necessary steps, from preparing the materials to securing the components together.

Lastly, enhancing air circulation within the housing is vital for optimal performance. I will discuss strategies to improve air flow and ventilation, ensuring that the air purifier functions efficiently.

Material Selection Tips

The best materials for building an industrial air purifier are those that have high durability and resistance to wear and tear. When selecting materials, it is essential to consider their ability to withstand the demands of continuous operation and the maintenance requirements that come with it.

Here are five key factors to consider:

- High-quality metal alloys: These provide strength and resilience to the overall structure of the air purifier.

- Impact-resistant plastics: They offer durability without adding unnecessary weight to the unit.

- Corrosion-resistant coatings: These protect the surfaces from degradation caused by exposure to moisture or harsh chemicals.

- Reinforced glass panels: They allow for visibility while ensuring safety and protection.

- Sturdy rubber seals and gaskets: These prevent air leaks and maintain the integrity of the system.

By choosing materials with these qualities, air purifier maintenance becomes easier, and the longevity of the filters and overall performance of the unit can be maximized.

Now, let’s move on to the assembly step-by-step.

Assembly Step-By-Step

After carefully selecting the necessary materials for building an industrial air purifier, it is time to move on to the assembly process. This step-by-step guide will provide detailed instructions on how to successfully assemble the air purifier.

To begin, gather all the components that were selected during the material selection process. Lay them out in an organized manner for easy access. Start by attaching the filter housing to the main body of the purifier, ensuring a secure fit.

Next, connect the fan to the motor, making sure that the blades are aligned properly. Once the fan is securely attached, it is time to connect the motor to the power supply. Double-check all connections to ensure they are tight and secure.

Finally, test the air purifier by turning it on and verifying that the fan is running smoothly and efficiently. If any issues arise during the assembly process, troubleshooting techniques should be employed. This may involve checking all connections, ensuring proper alignment, or consulting the manufacturer’s instructions for guidance.

Enhancing Air Circulation

To enhance air circulation, you should position the fan in a strategic location to maximize airflow. Here are some key factors to consider for improving air quality and reducing respiratory issues:

-

Fan placement: Position the fan near the source of pollutants or in an area with poor air circulation to ensure efficient removal of contaminants.

-

Fan speed: Adjust the fan speed according to the size of the room and the level of air pollution. Higher speeds may be needed for larger spaces or higher levels of pollutants.

-

Directional airflow: Direct the fan towards areas where people spend the most time, such as living rooms or bedrooms, to ensure they receive the benefits of improved air circulation.

-

Obstacle-free placement: Keep the fan away from furniture or other objects that could obstruct airflow and reduce its effectiveness.

-

Regular maintenance: Clean the fan blades and filters regularly to prevent the buildup of dust and pollutants, ensuring optimal performance.

By implementing these strategies, you can enhance air circulation, improve air quality, and reduce respiratory issues.

Now let’s move on to the next section, where we will discuss installing and wiring the purification mechanism.

Installing and Wiring the Purification Mechanism

Before you can install and wire the purification mechanism, make sure you have all the necessary tools and materials.

It is crucial to follow wiring safety precautions to ensure a safe and effective installation process. First and foremost, always turn off the power supply before working with any electrical components. Use insulated gloves and tools to minimize the risk of electrocution.

When connecting wires, ensure they are securely fastened and properly insulated to prevent any short circuits or electrical fires.

Additionally, it is essential to troubleshoot common issues that may arise during the installation process. These can include loose connections, faulty wiring, or incorrect voltage.

Testing and Fine-tuning the Air Purifier

Once you have completed the installation and wiring process, it’s time to test and fine-tune your air purification system. Here are some fine-tuning techniques and air quality testing methods to ensure optimal performance and effectiveness:

- Use an air quality monitor to measure the initial air quality and pollutants present in the environment.

- Adjust the fan speed and airflow settings to achieve the desired level of air circulation and purification.

- Test the system’s noise levels and make adjustments to minimize any disruptive sounds.

- Check the filter efficiency regularly and replace or clean filters as needed.

- Conduct periodic air quality tests to ensure the system is effectively removing pollutants.

By implementing these fine-tuning techniques and air quality testing methods, you can optimize the performance of your air purification system and create a healthier indoor environment.

Now, let’s move on to maintenance and troubleshooting tips for longevity.

Maintenance and Troubleshooting Tips for Longevity

Regularly cleaning and replacing filters, as well as addressing any maintenance issues promptly, will help ensure the longevity and efficient functioning of your air purification system.

Maintenance techniques are crucial to keep your air purifier running smoothly. Start by checking and cleaning the pre-filter regularly to prevent clogging and optimize airflow. Clean the main filter according to the manufacturer’s instructions, usually every 3-6 months. Additionally, inspect the fan and motor for any signs of wear or damage, and lubricate if necessary.

Troubleshooting methods are also important for identifying and resolving any issues with your air purifier. If you notice a decrease in performance, check for any blockages or obstructions in the air intake and exhaust. If the unit is not turning on, ensure it is properly plugged in and try resetting it.

Frequently Asked Questions

How Much Noise Does an Industrial Air Purifier Typically Make?

Typically, industrial air purifiers produce a significant amount of noise due to their powerful motors and fans. However, there are several ways to reduce noise levels, such as using soundproofing materials and designing efficient airflow systems.

What Is the Average Lifespan of the Components Used in an Industrial Air Purifier?

The average lifespan of components used in an industrial air purifier varies depending on the quality and maintenance. Regular cleaning and replacing filters can extend their longevity.

Can an Industrial Air Purifier Remove All Types of Air Pollutants?

Yes, an industrial air purifier can effectively remove various types of air pollutants. Through advanced filtration systems and technologies, it can capture and eliminate particles, gases, and chemicals, ensuring cleaner and healthier air quality.

Are There Any Safety Precautions to Consider When Operating an Industrial Air Purifier?

When operating an industrial air purifier, it is crucial to consider safety precautions. This includes proper maintenance to ensure optimum performance and reduce any potential hazards.

How Often Should the Filters Be Replaced in an Industrial Air Purifier?

I clean industrial air purifier filters regularly to maintain optimal performance. Regular maintenance benefits industrial air purifiers by ensuring clean air quality and prolonging the lifespan of the equipment.

Conclusion

After carefully selecting the right components and understanding air filtration systems, it is important to design an efficient air circulation system. Building the housing, and installing and wiring the purification mechanism are also crucial steps.

Once the purifier is built, it is necessary to thoroughly test and fine-tune it to ensure optimal performance and efficiency. Following maintenance and troubleshooting tips is also important to ensure the longevity of the purifier.

By following these steps and paying attention to every detail, you can create a powerful and reliable industrial air purifier that will provide clean and healthy air for your environment.