Nano-confined catalysts improve air purification by trapping active sites within tiny structures, making pollutant breakdown more efficient and selective. Surface modification techniques enhance their interaction with airborne pollutants like VOCs, NOx, and particulates, boosting stability and lifespan. These catalysts resist degradation, maintain performance longer, and target specific harmful substances more effectively. If you keep exploring, you’ll discover how these advancements can lead to healthier, cleaner air and smarter purification systems.

Key Takeaways

- Nano-confined catalysts trap active sites within tiny structures, enhancing reaction efficiency and pollutant removal.

- Surface modification techniques tailor catalyst surfaces for improved interaction and selectivity toward airborne pollutants.

- Protective coatings prevent nanoparticle aggregation, ensuring long-term stability and sustained air purification performance.

- Modifying surface chemistry enables targeted removal of specific pollutants like VOCs, NOx, and particulate matter.

- These advanced catalysts contribute to cleaner air, reduced emissions, and increased environmental sustainability.

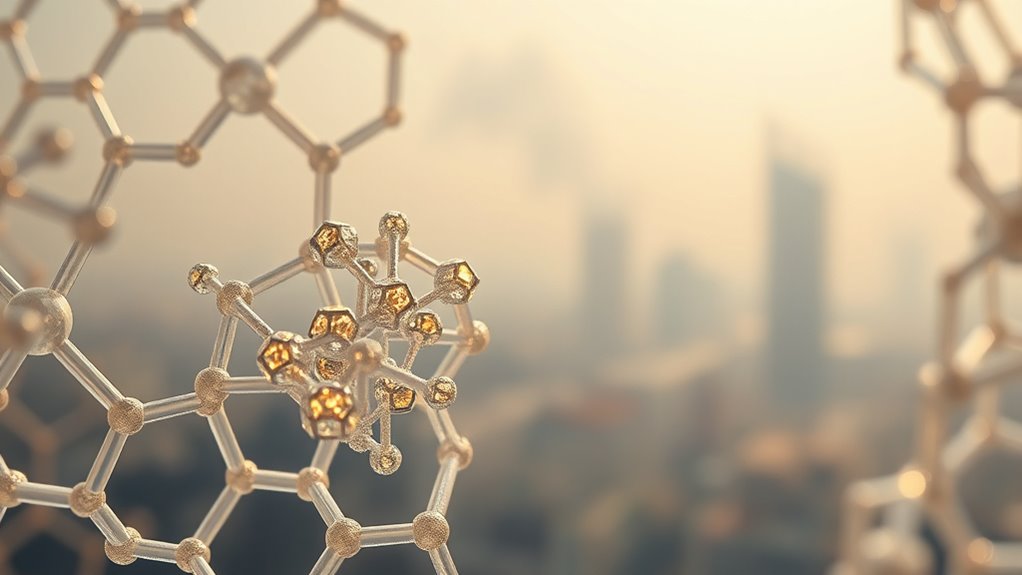

Nano-confined catalysts are revolutionizing chemical reactions by trapping active sites within tiny structures, which substantially enhances their efficiency and selectivity. When it comes to air purification, this innovation allows you to target pollutants more effectively, ensuring cleaner, healthier air. One of the key advantages of nano-confined catalysts is their improved nanoparticle stability. By confining nanoparticles within specific nanostructures, you prevent them from aggregating or degrading over time, which maintains their catalytic activity longer. This stability is essential for continuous air purification systems, where catalysts need to operate reliably over extended periods without losing effectiveness.

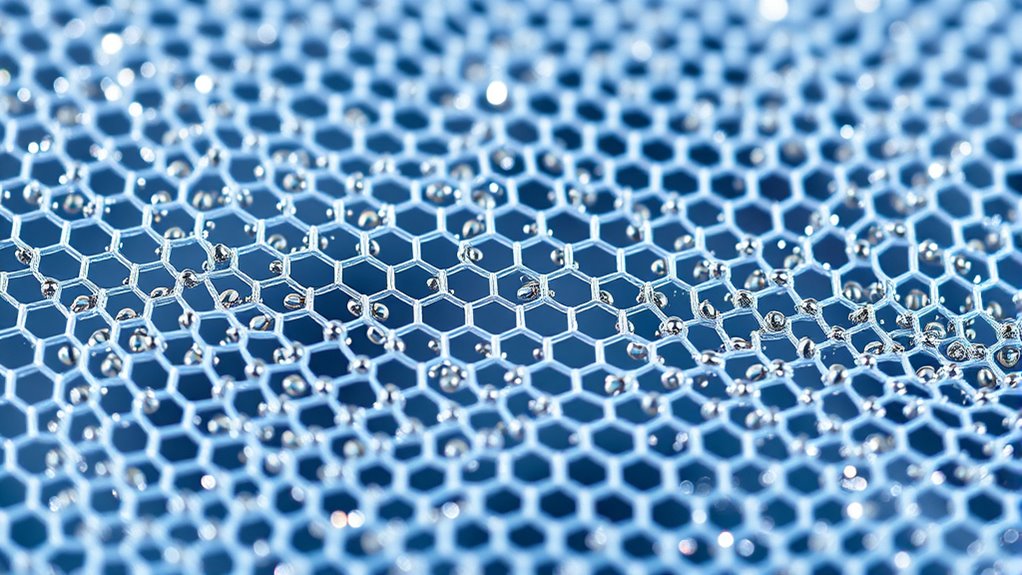

Surface modification techniques play a critical role in optimizing these nano-confined catalysts for air purification applications. By applying precise surface modifications, you can tailor the catalyst’s surface properties—such as hydrophilicity, charge, or functional groups—to better interact with specific airborne pollutants. For instance, adding oxygen-containing groups can enhance the catalyst’s ability to break down volatile organic compounds (VOCs), while other modifications might improve its affinity for nitrogen oxides or particulate matter. These techniques allow you to fine-tune the catalyst’s activity, selectivity, and resistance to deactivation, which are all pivotal for effective air cleaning.

In practice, surface modification often involves methods like chemical grafting, atomic layer deposition, or plasma treatments. These processes enable you to create uniform, durable coatings that enhance nanoparticle stability and pollutant adsorption. For example, coating nanoparticles with silica or metal oxides can provide a protective barrier, preventing sintering at high temperatures and ensuring long-term stability. Similarly, functionalizing the catalyst surface with specific groups can increase the rate at which pollutants are converted into harmless byproducts, improving overall efficiency.

Furthermore, harnessing surface modification techniques allows you to design catalysts that are selective toward certain pollutants, minimizing unwanted side reactions. This selectivity is particularly important in complex indoor or outdoor environments, where multiple pollutants coexist. By controlling the surface chemistry, you can develop catalysts that preferentially target harmful substances like nitrogen oxides or formaldehyde while remaining inert to benign particles. Additionally, insights from sound healing science suggest that understanding vibrational interactions could inspire innovative approaches to catalyst activation and regeneration, further enhancing their longevity and performance.

Frequently Asked Questions

How Long Do Nano-Confined Catalysts Typically Last in Air Purifiers?

Nano-confined catalysts typically last between 6 to 12 months in air purifiers, depending on usage and environment. Your catalyst lifespan can be influenced by durability factors like particle accumulation, humidity, and air pollutants. To maximize their lifespan, guarantee regular maintenance and replace filters as recommended. Keeping the purifier in a clean, dry area also helps maintain catalyst effectiveness, ensuring cleaner air over time.

Are Nano-Confined Catalysts Safe for Human Health and the Environment?

Nano-confined catalysts are generally considered safe for human health and the environment when properly used. They minimize health implications by reducing the release of harmful particles and byproducts. Additionally, their design limits environmental impact by enhancing efficiency and reducing waste. However, it is crucial to follow safety guidelines and regulations, as improper handling could pose risks. Overall, with proper management, nano-confined catalysts offer a safer, eco-friendly option for air purification.

Can Nano-Confined Catalysts Remove All Types of Airborne Pollutants?

You can’t catch all the flies with one swat, and nano-confined catalysts can’t remove every airborne pollutant. While they’re highly effective against specific pollutants like VOCs and certain gases, their pollutant specificity limits their scope. Catalyst limitations mean some particles, like ultrafine PM or complex chemicals, may slip through. So, while powerful, these catalysts aren’t a one-size-fits-all solution for air purification.

What Are the Costs Associated With Implementing Nano-Confined Catalyst Technology?

Implementing nano-confined catalyst technology involves costs linked to economic feasibility and manufacturing challenges. You’ll face expenses related to advanced materials, precise fabrication processes, and quality control. While initial investments may be high, the long-term benefits, like improved air purification efficiency and reduced maintenance, can offset costs. However, scaling production while maintaining consistency remains a key challenge, so careful planning and investment are essential for successful implementation.

How Do Nano-Confined Catalysts Compare to Traditional Catalysts in Efficiency?

You’ll find nano-confined catalysts outshine traditional ones, no contest. They boast superior surface stability, resisting degradation longer, and accelerate reaction kinetics, making purification faster and more efficient. While traditional catalysts might limp along, nano-confined ones thrive in tight spaces, optimizing every reaction. So, if you want cleaner air pronto, these tiny marvels deliver, proving that small really is mighty when it comes to catalytic performance.

Conclusion

Imagine these nano-confined catalysts as tiny superheroes patrolling your air, silently battling pollutants with precision. Their unique confinement boosts efficiency, making air purification more effective than ever. By harnessing their power, you can breathe easier, knowing you’re protected by a microscopic army working tirelessly behind the scenes. As small as they are, these catalysts pack a punch, transforming your environment into a cleaner, fresher space—proof that sometimes, the tiniest heroes make the biggest difference.