To implement predictive maintenance for your HVAC filters and components, you need calibrated sensors that provide accurate, real-time data on system performance. This data helps identify early signs of issues like clogged filters or failing fans, enabling proactive maintenance. Using analytics, you can optimize schedules, improve efficiency, and extend equipment life. Maintaining sensor calibration is essential for reliable insights, and you’ll discover how to set up an effective system to save costs and boost reliability.

Key Takeaways

- Regular sensor calibration ensures accurate data collection for monitoring HVAC filter cleanliness and component performance.

- Data analytics detects early signs of filter clogging and component wear, enabling proactive maintenance.

- Precise sensor data helps optimize system operations, reducing energy consumption and extending equipment lifespan.

- Continuous monitoring and predictive analytics facilitate maintenance scheduling based on actual system conditions.

- Accurate, timely data prevents costly repairs, minimizes downtime, and improves overall HVAC system efficiency.

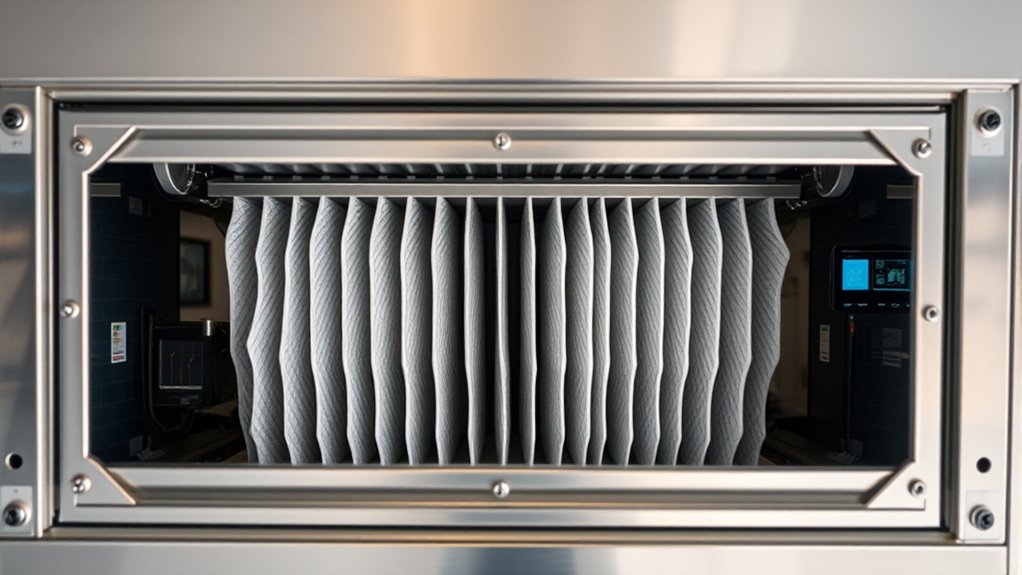

Have you ever wondered how to keep your HVAC system running efficiently and avoid costly breakdowns? One of the most effective ways is through predictive maintenance, which relies on understanding the real-time condition of your system’s components. At the core of this approach is sensor calibration. When sensors are properly calibrated, they provide accurate data about temperature, humidity, airflow, and filter cleanliness. Accurate sensors mean you can trust the information they relay, preventing false alarms or overlooked issues. Regular sensor calibration ensures that your data remains precise over time, especially as sensors can drift from their original settings. This accuracy is essential because it directly influences your ability to detect early signs of wear or failure before they escalate into major problems.

Data analytics plays a pivotal role here. By collecting data from calibrated sensors, you can analyze patterns and trends that signal impending issues. For example, if data analytics reveals that airflow rates are consistently decreasing, it might indicate a clogged filter or a failing fan motor. Instead of waiting for a breakdown, you get proactive alerts that prompt timely maintenance. This approach minimizes downtime and extends the lifespan of your HVAC components. Data analytics can also help you optimize your maintenance schedules, ensuring you service filters and parts only when necessary, rather than on a fixed timetable. This not only saves money but also reduces unnecessary disruptions.

Implementing predictive maintenance with sensor calibration and data analytics also means you gain better control over energy efficiency. When sensors accurately report system conditions, you can fine-tune operations to ensure your HVAC runs at peak performance. For example, detecting slight deviations in temperature or pressure early on allows adjustments that prevent overworking the system. As a result, your energy costs drop, and your system’s lifespan increases. Additionally, by continuously analyzing the data, you can identify recurring issues or inefficiencies, helping you develop long-term strategies for maintenance and upgrades. Moreover, understanding the importance of security vulnerabilities in your systems can help prevent data breaches that compromise your maintenance data and operational integrity.

Frequently Asked Questions

How Often Should Predictive Maintenance Be Performed on HVAC Systems?

You should perform predictive maintenance on your HVAC system every three to six months. Regular checks help monitor filter lifespan and guarantee components operate efficiently. By scheduling maintenance proactively, you prevent unexpected breakdowns and extend equipment life. Keep an eye on performance indicators, and adjust your maintenance schedule based on system usage and environmental factors. Consistent upkeep saves money and maintains ideal indoor air quality.

What Are the Costs Associated With Implementing Predictive Maintenance?

They say, “A penny saved is a penny earned,” and that’s true for predictive maintenance costs. You’ll need to conduct a thorough cost analysis and include initial investments in sensors and software, ongoing maintenance, and staff training. While upfront costs may seem high, effective budget planning can reduce unexpected repairs and downtime, ultimately saving money in the long run. The investment pays off with increased efficiency and system longevity.

Can Predictive Maintenance Prevent All HVAC System Failures?

Predictive maintenance can’t prevent all HVAC system failures, but it markedly reduces them by monitoring factors like filter lifespan and sensor accuracy. You can catch issues early, avoiding costly repairs and downtime. However, some failures result from unforeseen events or sensor inaccuracies, so ongoing maintenance and system checks remain essential. While it improves reliability, it’s not a guarantee against every failure, but a valuable tool in your maintenance strategy.

How Does Predictive Maintenance Impact Energy Efficiency?

Think of your HVAC system like a car; when well-maintained, it runs smoothly and uses less fuel. Predictive maintenance boosts energy savings by catching issues early, allowing for system enhancement before problems escalate. This proactive approach ensures your HVAC runs efficiently, reducing waste and lowering energy bills—much like tuning a car for peak performance. You’ll notice better comfort and cost savings with less energy consumption.

What Training Is Required for Staff to Manage Predictive Maintenance Tools?

To manage predictive maintenance tools effectively, you need to undergo specific training requirements focused on skill development. This includes learning how to interpret data from sensors, operate maintenance software, and troubleshoot issues. You should also be familiar with the HVAC system’s components to make informed decisions. Regular hands-on practice and ongoing education help you stay updated on new technologies, ensuring you can optimize system performance and prevent costly breakdowns.

Conclusion

Implementing predictive maintenance for your HVAC filters and components might seem costly upfront, but it saves you money long-term by preventing unexpected breakdowns and improving system efficiency. Don’t let concerns about initial investment hold you back. With smarter maintenance schedules, you’ll reduce downtime and extend equipment lifespan. Take control of your HVAC system today—invest in predictive maintenance and enjoy reliable, cost-effective comfort all year round.