Calibrating low-cost PM sensors can improve accuracy but has limits. You can often compare your sensors to reference monitors or use correction algorithms to adjust their readings. However, full accuracy like laboratory-grade devices isn’t possible without professional calibration. Regular calibration helps counter sensor drift caused by environmental factors and aging. If you want to understand what methods work best for your setup and their limitations, keep exploring how calibration can maximize your sensor’s reliability.

Key Takeaways

- Calibration can improve low-cost PM sensor accuracy but cannot fully replicate reference-grade instruments.

- Co-location with reference monitors helps develop correction factors, yet environmental differences limit effectiveness.

- Laboratory calibration provides precise initial validation but is less practical for ongoing field use.

- Regular calibration routines are essential to counteract sensor drift over time caused by aging and contamination.

- Complex algorithms and firmware adjustments can enhance calibration but cannot fully eliminate inherent sensor limitations.

Low-cost particulate matter (PM) sensors have become popular for monitoring air quality due to their affordability and ease of use. However, their performance can be compromised over time because of sensor drift, which is a gradual change in sensor response that causes readings to become inaccurate. This drift can result from environmental factors like humidity, temperature fluctuations, or sensor aging. To maintain data accuracy, it’s essential to regularly address sensor drift through appropriate calibration methods. Calibration isn’t a one-time fix; it’s an ongoing process that helps guarantee your sensor’s measurements stay reliable.

Low-cost PM sensors require regular calibration to counteract drift and ensure accurate air quality measurements.

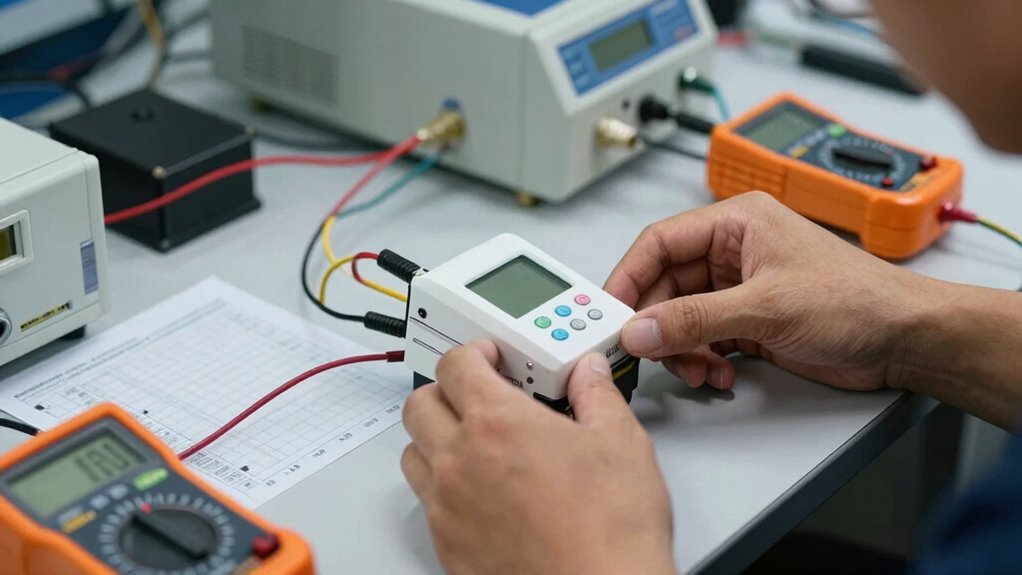

When tackling sensor drift, you have several calibration methods at your disposal. The most common approach involves co-locating your low-cost sensor with a reference-grade monitor. By comparing readings over a given period, you can develop a correction factor or algorithm that aligns your sensor’s output with trusted standards. This method works well if you have access to reference equipment and can perform periodic calibration checks. Another approach involves laboratory calibration, where sensors are tested against known concentrations of particulates in controlled environments. While more precise, this method is less practical for everyday monitoring but useful for initial sensor validation or research.

You should also consider field calibration techniques, which are designed for real-world conditions. These methods often involve using portable reference monitors or integrating calibration algorithms directly into the sensor’s firmware. Some users implement simple linear adjustments, while others develop more complex models based on environmental variables. Regardless of the chosen method, it’s important to perform calibration regularly, especially if you notice drifting readings over time. Doing so minimizes inaccuracies caused by sensor aging, environmental changes, or contamination. Regular calibration is crucial for maintaining the reliability of your air quality data over the long term.

Keep in mind that no calibration method is perfect; each has limitations. For example, co-location calibration assumes that the environmental conditions at the reference site are representative of your measurement location, which isn’t always true. Calibration models may also need periodic updates to account for evolving sensor characteristics. The key is to establish a consistent calibration routine tailored to your specific sensor type and monitoring environment. This way, you can better account for sensor drift and maintain the integrity of your air quality data.

Ultimately, understanding and managing sensor drift through effective calibration methods is imperative for extracting meaningful insights from low-cost PM sensors. While they can’t match the precision of reference-grade instruments, proper calibration ensures your measurements remain as accurate as possible, empowering you to make informed decisions about air quality in your environment.

Frequently Asked Questions

Can Low-Cost Sensors Accurately Measure All Particulate Sizes?

You can’t rely on low-cost sensors to accurately measure all particle sizes. They tend to perform well with larger particles but struggle with smaller ones, affecting measurement accuracy. Variations in particle size influence the sensor’s ability to detect and quantify particulate matter precisely. While they provide useful general estimates, for detailed and accurate particle size measurement, more sophisticated, higher-cost equipment is necessary.

How Often Should Calibration Be Performed for Optimal Accuracy?

You should calibrate your low-cost PM sensors regularly, ideally every few weeks or monthly, to account for sensor drift that can affect accuracy. Frequent calibration helps maintain reliable measurements, especially in changing environmental conditions. Keep an eye on any deviations or inconsistent readings, and adjust calibration frequency if you notice increased drift over time. Consistent calibration guarantees your sensor’s data remains as accurate as possible for your needs.

Are There Specific Environments Where Calibration Is Unnecessary?

In some outdoor environments, calibration might be less necessary, especially if conditions are stable and predictable. For example, in a rural area with minimal pollution fluctuations, sensors may maintain accuracy longer without frequent calibration. However, in industrial settings with variable pollutants and harsh conditions, regular calibration remains vital. You should assess environmental stability before skipping calibration, but never rely solely on initial calibration for long-term accuracy.

What Are the Costs Associated With Professional Calibration Services?

You should expect professional calibration services to cost anywhere from $100 to $300 per sensor, depending on the provider and calibration complexity. Cost considerations include travel fees, lab testing, and equipment used. Service options range from on-site calibration to sending sensors to certified labs. While investing in calibration can guarantee accuracy, weigh these costs against your project needs and whether DIY calibration might suffice for your application.

Can Calibration Improve Sensor Lifespan and Durability?

Did you know that regular calibration can extend sensor lifespan by up to 30%? By maintaining calibration frequency, you help reduce sensor degradation, ensuring your low-cost PM sensors remain accurate longer. Proper calibration minimizes wear and tear from incorrect readings, preserving durability. So, yes, consistent calibration not only improves accuracy but also enhances the longevity of your sensors, saving you money and hassle over time.

Conclusion

So, while it’s tempting to think a simple calibration can turn a cheap sensor into a precision instrument, don’t be fooled. These devices may seem promising, but their limitations remind you that accuracy isn’t just about tweaking a few numbers. Ironically, for all the fuss about affordability, you might still end up spending more time and money trying to get meaningful data. Sometimes, the most affordable option is knowing when to accept the limits of low-cost sensors.