To stop sensor drift with a simple calibration routine, regularly adjust your sensors using traceable standards based on the manufacturer’s guidelines. Schedule calibrations based on your sensor type, environment, and usage complexity, aiming for consistency—whether daily, weekly, or monthly. Document each calibration to track performance over time. Proper routine calibration keeps your sensors accurate, extending their lifespan and ensuring data integrity. Keep exploring for detailed tips on maintaining ideal sensor performance.

Key Takeaways

- Regularly schedule calibration sessions based on sensor usage and environmental conditions.

- Use traceable, certified calibration standards to ensure accuracy during adjustments.

- Document calibration results to identify patterns and predict future drift trends.

- Focus calibration efforts on critical sensors influencing overall system performance.

- Automate calibration checks or incorporate self-calibration features when available.

Have you ever wondered why sensors sometimes give inaccurate readings over time? It’s a common question, especially if you rely on precise measurements for your work or processes. The answer often comes down to sensor drift, which affects sensor stability—the ability of a sensor to provide consistent and reliable data. Over time, sensors can become less stable due to factors like environmental changes, aging components, or contamination. This drift can cause readings to gradually shift, leading to inaccuracies that might compromise your data quality or system performance.

To combat this, understanding and managing calibration frequency is vital. Calibration is the process of adjusting your sensor’s output to match a known standard, guaranteeing that its readings remain accurate over time. The key is finding a balance: calibrate too often, and you waste time and resources; calibrate too infrequently, and you risk letting inaccuracies go unnoticed. Regular calibration routines help maintain sensor stability, preventing small drifts from snowballing into significant errors. By establishing a consistent calibration schedule—whether daily, weekly, or monthly—you keep your sensors functioning at their best. This routine acts as a proactive measure, catching deviations early and preventing sensor drift from impacting your operations.

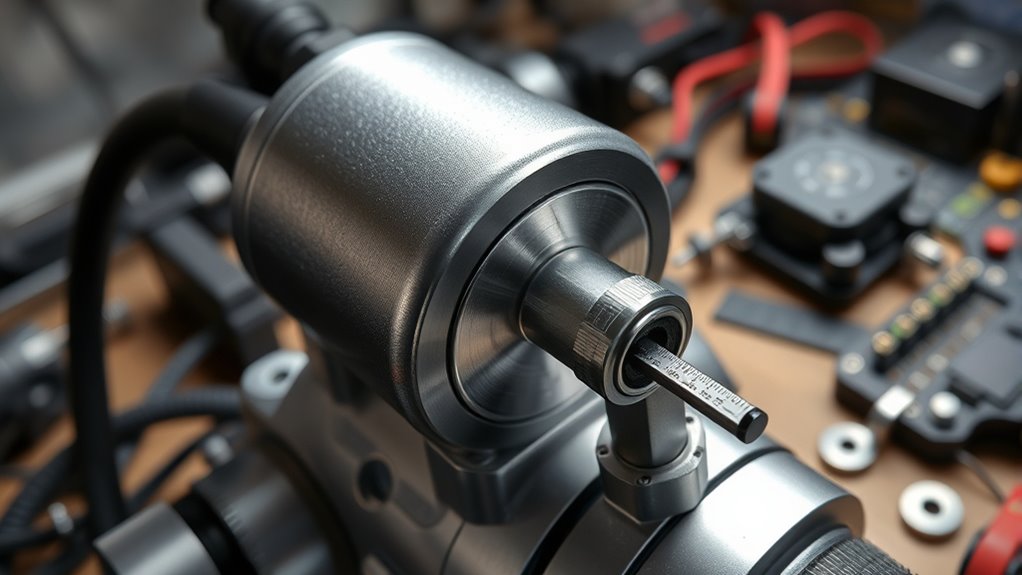

Implementing a simple calibration routine doesn’t have to be complicated. Start by identifying the critical sensors that influence your processes and set a calibration interval based on their stability history and operational demands. Use traceable calibration standards for accuracy, and document each calibration to track trends over time. This record-keeping can reveal patterns, such as sensors that drift faster and require more frequent attention. Additionally, integrating automated calibration checks or self-calibration features, if available, can streamline the process and reduce human error. Recognizing the expiration of vape juice and other consumables can also help in maintaining optimal device performance.

Maintaining sensor stability through disciplined calibration routines is a straightforward yet effective way to stop sensor drift from undermining your measurements. Remember, the smaller and more frequent adjustments you make, the less likely small drifts will accumulate into serious inaccuracies. Regular calibration not only prolongs the lifespan of your sensors but also guarantees the integrity of your data, giving you confidence in every reading. Ultimately, a proactive approach to calibration is your best defense against sensor drift, keeping your measurements precise and your system running smoothly.

Frequently Asked Questions

How Often Should Sensor Calibration Be Performed?

You should perform sensor calibration regularly to account for sensor aging, which can cause drift over time. The calibration frequency depends on your specific sensor and application, but generally, it’s recommended to calibrate at least once every few months. Monitoring sensor performance helps identify drift early, ensuring accurate readings. Consistent calibration routines prevent errors from accumulating, maintaining the reliability of your measurements and extending your sensor’s lifespan.

Can Calibration Routines Be Automated?

Imagine a silent guardian watching over your sensors. Yes, calibration routines can be automated, acting like vigilant sentinels. Using automated calibration, drift detection occurs in real-time, ensuring sensors stay accurate without manual intervention. This continuous watch minimizes errors and maintains precision effortlessly. With automation, you gain peace of mind, trusting your sensors to self-correct and perform flawlessly, freeing you from tedious manual calibrations.

What Are the Signs of Sensor Drift?

You’ll notice sensor drift through inconsistent readings or deviations from expected data, which can signal reduced sensor longevity. Regular calibration techniques help detect these signs early, guaranteeing accurate measurements. If your sensor starts showing erratic outputs or fails to respond correctly, it’s time to recalibrate. Keeping an eye on these indicators allows you to maintain sensor performance, extend its lifespan, and ensure reliable data collection.

Are There Specific Environments That Accelerate Drift?

Environmental factors like extreme temperatures, humidity, and exposure to dust or chemicals can hasten sensor drift. These conditions cause sensors to degrade faster, making regular calibration essential. You should increase calibration frequency in such environments to maintain accuracy. By monitoring environmental influences and adjusting calibration schedules accordingly, you can ensure your sensors stay reliable and precise over time.

How Does Temperature Affect Calibration Accuracy?

Temperature affects calibration accuracy because fluctuations can cause sensor components to expand or contract, leading to instability. If your environment lacks temperature stability, calibration methods might become less reliable over time. To counteract this, you should perform calibrations in stable temperature conditions and consider using temperature compensation techniques. Maintaining a controlled environment helps guarantee your sensor remains precise, reducing drift caused by temperature variations.

Conclusion

By following this simple calibration routine, you’ll keep your sensors as accurate as a hawk’s eyesight, no matter how long they’ve been in use. Regular calibration prevents sensor drift from sneaking up on you, saving you countless hours of troubleshooting. It’s a quick fix that can make your measurements as reliable as the sunrise. Don’t let drift turn your precision into chaos—calibrate often and stay ahead of the game!