Using CFD modeling helps you analyze airflow patterns and determine ideal filter placement in your space. You can visualize air trajectories, identify dead zones, and see how adjustments improve air quality and efficiency. By testing different configurations virtually, you avoid costly mistakes and enhance system performance. This proactive approach saves energy and extends filter life. Keep exploring to discover how CFD can transform your ventilation and filtration strategies effectively.

Key Takeaways

- CFD modeling visualizes airflow patterns to identify dead zones and optimize ventilation strategies for better air quality.

- It allows virtual testing of filter placements to maximize contaminant capture and reduce energy consumption.

- CFD helps assess layout adjustments, improving airflow uniformity and overall system performance.

- Simulating various configurations proactively prevents costly modifications and tailors systems to specific spaces.

- CFD analysis enhances indoor air quality, promotes energy efficiency, and extends equipment lifespan through data-driven design.

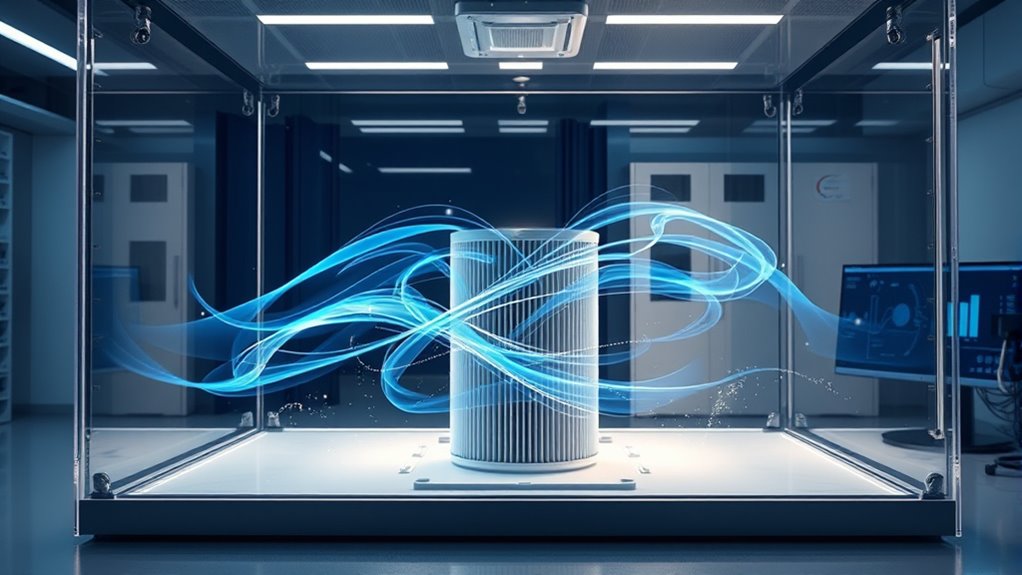

Computational Fluid Dynamics (CFD) modeling has become an essential tool for understanding and enhancing airflow and filtration systems. When you harness CFD, you gain detailed insights into how air moves within a space, allowing you to improve ventilation efficiency. Proper ventilation isn’t just about moving air; it’s about directing it where it’s needed most, minimizing dead zones, and ensuring contaminants are effectively removed. By simulating airflow patterns, CFD helps you identify areas where airflow stagnates or recirculates, which can compromise air quality. This understanding guides you in adjusting ventilation strategies to maximize efficiency, making indoor environments healthier and more comfortable.

CFD reveals airflow patterns to optimize ventilation and improve indoor air quality.

One of the key advantages of CFD is its ability to refine filter placement. Instead of relying on trial-and-error or standard configurations, you can virtually test different filter positions within your system. CFD simulations reveal how air interacts with filters, showing you where to place them for maximum effectiveness. Proper filter placement ensures that contaminated air is captured efficiently before it circulates throughout the space, reducing the likelihood of airborne pollutants reaching occupants. It also helps in decreasing pressure drops and energy consumption, as filters positioned appropriately require less fan power to maintain airflow rates.

As you explore different layouts through CFD, you’ll notice that even small adjustments can markedly impact overall system performance. For instance, repositioning a filter or modifying a vent can create more uniform airflow, eliminating areas with poor ventilation. This not only improves air quality but also extends the lifespan of your filters, saving you money in the long run. CFD allows you to visualize airflow trajectories and velocity profiles, making complex interactions understandable and actionable.

Furthermore, by iteratively testing various configurations digitally, you avoid costly modifications after installation. You can simulate various scenarios—like changing filter types or moving vents—to see which setup offers the best balance of airflow, filtration efficiency, and energy use. This proactive approach ensures your system is tailored precisely to your space’s needs, boosting ventilation efficiency and ensuring filters are used effectively. Additionally, understanding factors influencing airflow can help optimize your system further. Overall, CFD modeling empowers you to make data-driven decisions that enhance indoor air quality, reduce operational costs, and create healthier environments.

Frequently Asked Questions

How Cost-Effective Is Implementing CFD Modeling in Small Facilities?

Implementing CFD modeling in small facilities can be quite cost-effective if you conduct a thorough cost analysis beforehand. While initial setup costs may seem high, you save money long-term by optimizing airflow and filtration, reducing energy consumption, and preventing costly upgrades. Focus on practical implementation strategies like simplified models and phased integration to maximize benefits without overspending, making CFD a smart investment for small-scale operations.

Can CFD Models Adapt to Real-Time Airflow Changes?

Sure, CFD models can adapt to dynamic airflow and filter variability, but only if you’re willing to keep babysitting them like a high-maintenance pet. They can simulate real-time changes, but the process demands constant data updates and fine-tuning. So, while technically possible, don’t expect seamless adjustments. Instead, prepare for a continuous dance of tweaks, making your airflow management feel more like an ongoing soap opera than a smooth operation.

What Are Common Challenges in Validating CFD Simulation Results?

Validation hurdles often challenge you because real-world data discrepancies can make it hard to confirm CFD simulation accuracy. You might struggle with obtaining precise measurements, which are essential for comparison. Additionally, complex airflow patterns and turbulence can cause differences between simulated and actual results. These issues require careful calibration, high-quality data, and sometimes iterative adjustments to guarantee your CFD model reliably predicts real airflow and filtration behavior.

How Does CFD Modeling Account for Variable Filter Efficiencies?

Think of CFD modeling as a dynamic map that adapts to changing terrain. It accounts for variable filter efficiencies by incorporating detailed data on how filters perform under different conditions. As airflow varies, the model adjusts to reflect these changes, tracking how filter efficiency impacts airflow patterns. This way, you get a realistic picture of how filtration behaves in real-world scenarios, helping you optimize system performance effectively.

Is Specialized Training Required to Interpret CFD Simulation Data Effectively?

You don’t need specialized training to interpret CFD simulation data, but developing expertise requirements is helpful. With some familiarity, you can analyze airflow patterns and filtration efficiency effectively. However, for complex data interpretation, taking courses or collaborating with CFD experts enhances your understanding. This way, you ensure accurate insights and optimize your airflow and filtration systems efficiently without needing extensive prior experience.

Conclusion

By leveraging CFD modeling, you can accurately optimize airflow and filtration systems, ensuring better indoor air quality. While some believe airflow patterns have minimal impact on filtration efficiency, studies show that strategic adjustments can considerably reduce contaminants. Embracing CFD allows you to test these theories virtually, saving time and resources. Ultimately, understanding airflow dynamics isn’t just a theory—it’s a practical approach that leads to healthier, safer environments.