Ever thought about how to connect a salvaged air purifier motor? In this article, I will walk you through the process with detailed and straightforward instructions.

By understanding the motor components, identifying wire connections, and mapping the motor’s wiring diagram, you will be able to successfully wire the motor.

We will also cover connecting the power supply, securing the wire connections, and testing the motor’s functionality.

Let’s get started on this exciting DIY project!

Key Takeaways

- Understanding the wiring diagram is crucial for troubleshooting motor problems.

- Identifying wire color meanings helps determine the function of each wire.

- Proper wire placement is essential for correct electrical connections.

- Ensuring proper voltage requirements and taking safety precautions are vital during installation.

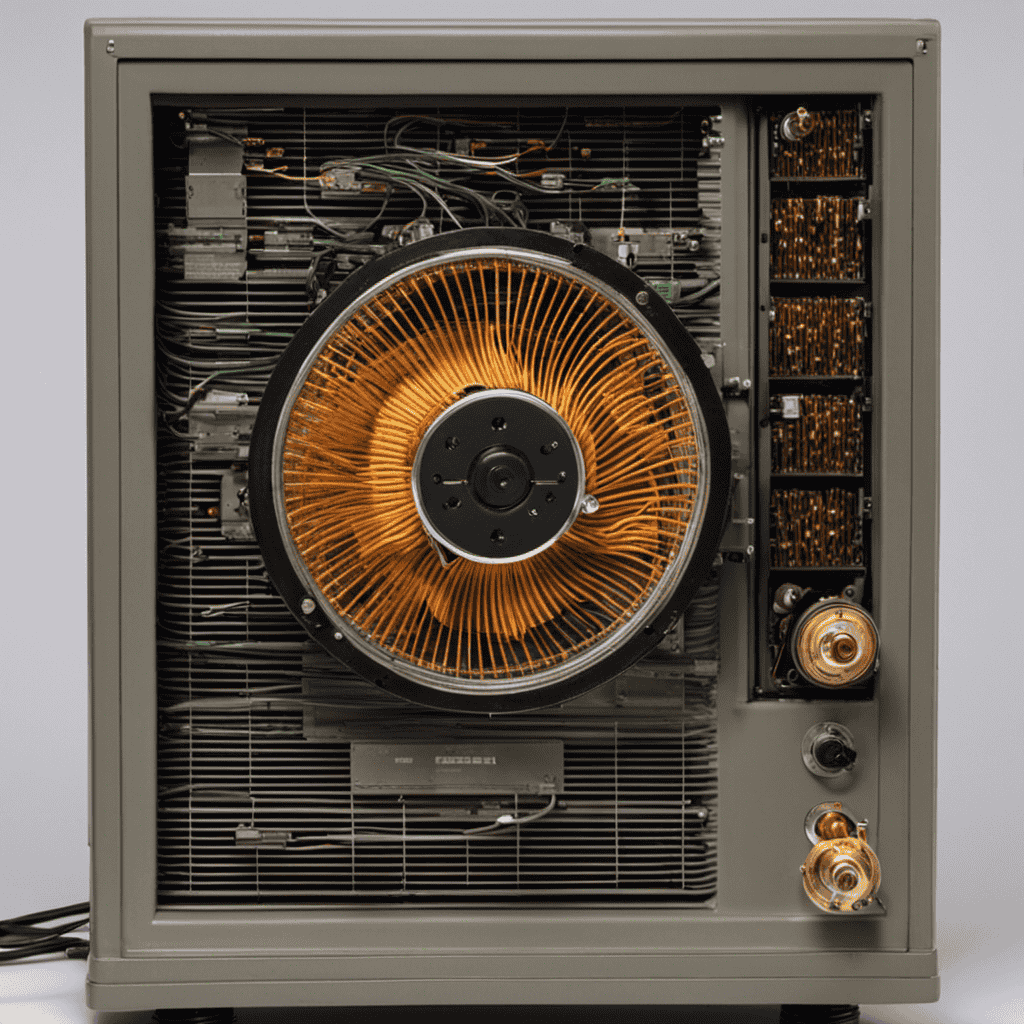

Understanding the Motor Components

To understand the motor components, you’ll need to examine the wiring diagram. This is crucial for motor troubleshooting and identifying common motor problems.

The first step is to locate the motor’s power source. It is typically connected to a power supply unit or a control board. Check for any loose or damaged wires that could be causing issues.

Next, inspect the motor’s capacitor, which helps with starting and running the motor smoothly. If the motor is not starting or is running erratically, a faulty capacitor could be the culprit.

Additionally, check the motor’s bearings for any signs of wear or damage. These are just a few examples of common motor problems that can be identified by understanding the motor components.

Moving forward, let’s now focus on identifying the wire connections.

Identifying the Wire Connections

When it comes to identifying wire connections, there are three key points to consider: wire color meanings, proper wire placement, and testing wire connections.

Understanding wire color meanings is crucial as it helps determine the function of each wire.

Proper wire placement ensures that the electrical connections are made correctly, preventing any potential hazards or malfunctions.

Lastly, testing wire connections is essential to ensure that the electrical circuit is functioning properly and to identify any potential issues before they become problematic.

Wire Color Meanings

The blue wire on the salvaged air purifier motor indicates the neutral connection.

When it comes to wire color coding, it is crucial to understand the meanings behind each color. This knowledge plays a significant role in troubleshooting wire connections. Different colors signify different functions and must be connected accordingly for the motor to operate safely and efficiently.

In addition to the blue wire representing the neutral connection, there are other wire colors to consider. For example, black is used for the hot or live wire, and green or bare copper is used for the ground wire.

Understanding these color codes ensures that you can identify and troubleshoot any wiring issues that may arise.

Now that we have covered wire color meanings, let’s move on to discussing the proper wire placement for the salvaged air purifier motor.

Proper Wire Placement

Make sure you place the wires in the correct positions to ensure proper operation of the motor.

When wiring a salvaged air purifier motor, it is crucial to identify wire gauges and troubleshoot common wiring issues.

To begin, determine the gauge of the wires by measuring their diameter using a wire gauge tool. This will help you choose the appropriate connectors and ensure a secure connection.

Additionally, check for any damaged or frayed wires that may cause a malfunction. If you encounter wiring issues, such as a motor that doesn’t start or runs at an incorrect speed, inspect the connections and make sure they are tightly secured.

It is also important to double-check the wiring diagram or consult the manufacturer’s instructions to ensure proper wire placement.

Following these steps will help you wire the salvaged air purifier motor correctly and avoid potential problems.

Testing Wire Connections

To ensure proper operation, you should always test the connections for any potential issues. When testing wire tension, it is crucial to check for secure and tight connections. Start by gently tugging on the wires to ensure they are firmly attached. If there is any give or movement, it indicates a loose connection that needs to be addressed.

Additionally, troubleshooting common wire connection issues involves checking for any signs of frayed or damaged wires. Look for any exposed copper or insulation that may have been compromised.

Moreover, make sure to verify that the wires are correctly connected according to the provided wiring diagram or instructions.

Disassembling the Motor Housing

Start by carefully removing the screws to access the inside of the motor housing.

Disassembling the motor housing requires precise techniques to ensure a successful salvage of the parts.

Begin by disconnecting any wires connected to the motor.

Use a small screwdriver to carefully pry open the housing, being cautious not to damage any internal components.

Once the housing is open, locate the motor assembly and carefully remove it from the housing.

Take note of any wires or connectors attached to the motor and disconnect them as needed.

Inspect the salvaged motor for any signs of damage or wear.

If necessary, consider using salvaged parts from other motors as alternatives to replace any damaged components.

Mapping the Motor’s Wiring Diagram

Using a small tool, I carefully trace the wires on the motor assembly to map out the wiring diagram. This step is crucial for motor troubleshooting and maintenance.

Here’s a detailed breakdown of the process:

-

Precision: Ensure accuracy by using a magnifying glass to examine the wires closely.

-

Patience: Take your time to avoid damaging the delicate wires during the tracing process.

-

Organization: Keep a notebook handy to jot down the wire colors and their corresponding connections.

-

Documentation: Capture clear photos of the wiring diagram for future reference.

Connecting the Power Supply

When connecting the power supply to a salvaged air purifier motor, there are several key points to consider.

First and foremost, it’s crucial to ensure that the proper voltage requirements are met in order to avoid damaging the motor or causing a safety hazard.

Additionally, referring to the motor’s wiring diagram will provide valuable guidance on how to correctly wire the motor to the power supply.

Lastly, it’s important to take appropriate safety precautions during the installation process to protect oneself from potential electrical hazards.

Proper Voltage Requirements

The salvaged air purifier motor’s voltage requirements depend on the specific model and should be checked before wiring. Proper voltage is essential for the motor to function optimally and prevent any damage.

Here are some key points to consider when dealing with motor maintenance and troubleshooting techniques:

-

Consult the manufacturer’s documentation: Refer to the user manual or technical specifications to determine the voltage requirements for your specific motor model.

-

Inspect the motor label: Look for any markings or labels on the motor itself that indicate voltage requirements.

-

Use a multimeter: Measure the voltage of the motor using a multimeter to ensure it matches the required voltage range.

-

Seek professional assistance: If you are unsure about the voltage requirements or encounter any issues, it is recommended to consult a professional electrician or technician for assistance.

Understanding the proper voltage requirements is crucial for ensuring the motor’s longevity and performance. Once you have determined the correct voltage, you can proceed with wiring the salvaged air purifier motor according to the provided wiring diagram guidance.

Wiring Diagram Guidance

Inspecting the provided wiring diagram guidance is crucial to ensure correct connection of the salvaged air purifier motor. This step is essential for understanding the motor wiring techniques and troubleshooting motor connections.

The wiring diagram provides precise information on how to connect the various wires of the motor. It outlines the different terminals and their corresponding functions. By carefully following the diagram, you can avoid any potential errors that could damage the motor or lead to malfunction.

Additionally, the diagram may include information on the color coding of the wires, which aids in identifying and connecting the correct wires.

Taking the time to study and comprehend the wiring diagram guidance is an important step in successfully wiring the salvaged air purifier motor.

Safety Precautions During Installation

To ensure your safety during installation, be mindful of the potential hazards and take necessary precautions. Here are some important safety tips to keep in mind:

- Wear protective gloves and safety goggles to prevent any injuries while handling the motor or any electrical components.

- Turn off the power supply before starting the installation process to avoid electric shocks.

- Use insulated tools to minimize the risk of electrical accidents.

- Follow the manufacturer’s instructions and guidelines carefully to ensure proper installation.

By following these safety precautions, you can minimize the chances of accidents and injuries during the installation process.

Now, let’s move on to the next step: securing the wire connections.

Securing the Wire Connections

Make sure you’re using wire nuts to secure the wire connections for the salvaged air purifier motor. When it comes to wire connection techniques, it’s crucial to ensure a secure and reliable connection.

One of the most common wire connection mistakes is not using the proper connectors. Wire nuts are specifically designed to join wires together, providing a secure and insulated connection.

To use wire nuts, strip about 1/2 inch of insulation from the wire ends, twist the stripped wire ends together, and then twist the wire nut onto the twisted wires in a clockwise motion until it is tight. This ensures a solid connection that won’t come loose.

Once the wire connections are properly secured, you can move on to testing the motor’s functionality and ensure that everything is working as expected.

Testing the Motor’s Functionality

Now that you have secured the wire connections, it’s time to test the functionality of the motor and make sure everything is working properly. To troubleshoot motor issues, it’s important to be aware of common motor problems that may arise.

Here are four common issues to watch out for and how to address them:

-

No power: Check if the motor is receiving power by testing the voltage with a multimeter. Ensure that the power source is properly connected and the circuit breaker is not tripped.

-

Motor won’t start: Check if the motor’s start capacitor is faulty and needs replacement. Inspect the wiring for any loose connections or damaged wires that may be causing the issue.

-

Motor runs but makes strange noises: This could indicate worn-out bearings. Lubricate the bearings or replace them if necessary.

-

Overheating: Excessive heat can damage the motor. Check for any blockages or obstructions in the air vents and clean them if needed. Also, ensure that the motor is properly sized for the load it is carrying.

Conclusion

In conclusion, wiring a salvaged air purifier motor can be a complex task, but with careful understanding and following the proper steps, it can be successfully accomplished.

For example, let’s consider a hypothetical case where an individual salvages a motor from an old air purifier and successfully wires it to create a DIY ventilation system for their workshop.

By carefully disassembling, mapping the wiring diagram, and connecting the power supply, they were able to secure the wire connections and test the motor’s functionality.

This allowed them to create a functional and cost-effective ventilation solution for their workspace.